Content Menu

● What is Quenching?

● The Role of Quenching Systems in Modern Industry

● Types of Quenching Systems and Media

>> Water Quenching

>> Oil Quenching

>> Polymer Quenching

>> Gas/Air Quenching

● Key Features to Consider When Choosing a Quenching System

● Top Quenching System Manufacturers and Suppliers in France

>> ECM Technologies

>> CIMCOOL (DuBois Chemicals)

>> BMI Fours

>> GTM France SAS

>> Thermi-Lyon Group

● Innovations and Trends in French Quenching Systems

>> Automation and Digitalization

>> Energy Efficiency and Sustainability

>> Customization and Modular Design

>> Advanced Materials and Applications

● Case Study: Aluminum Quenching in France

>> Drop-Bottom Furnace Technology

>> Benefits for OEMs and Exporters

● The Export Advantage: Why Choose French Suppliers?

● Conclusion

● Frequently Asked Questions

>> 1. What is the primary advantage of oil-based quenching systems?

>> 2. Are polymer quenching systems suitable for aluminum alloys?

>> 3. How do French quenching system manufacturers support global OEMs?

>> 4. What safety considerations are important in quenching operations?

>> 5. Can quenching systems be integrated with automated production lines?

In the ever-evolving world of metalworking and heat treatment, quenching systems are critical for achieving the desired mechanical properties of metals, especially aluminum and steel. For international OEMs, wholesalers, and manufacturers seeking reliable quenching system manufacturers and suppliers in France, understanding the technological landscape and the leading players is essential. This comprehensive article explores the top French quenching system manufacturers and suppliers, the advanced technologies they offer, and practical insights into their applications, with a special focus on the needs of global partners.

What is Quenching?

Quenching is the rapid cooling of metals after they have been heated to a specific temperature, typically above their recrystallization point. The main goal is to alter the metal's microstructure, significantly enhancing its hardness and strength. This process is a critical step in heat treatment, often followed by tempering to relieve internal stresses and improve toughness.

Quenching is essential in the production of high-performance metal components. By controlling the cooling rate, manufacturers can achieve specific properties such as increased hardness, improved wear resistance, and enhanced durability. The choice of quenching method and medium directly influences the final characteristics of the material.

The Role of Quenching Systems in Modern Industry

Quenching systems are vital for industries such as automotive, aerospace, construction, and machinery manufacturing. They ensure:

- Consistent Product Quality: Controlled cooling rates guarantee uniformity in mechanical properties across batches.

- Enhanced Mechanical Properties: Proper quenching increases hardness, wear resistance, and tensile strength.

- Minimized Distortion and Cracking: Selecting the right quenching media and system design reduces the risk of defects.

- Process Efficiency and Repeatability: Automated systems enable high-throughput, reliable production, crucial for OEM supply chains.

The demand for advanced quenching systems is rising as industries push for higher performance and tighter quality control. French manufacturers are at the forefront of this technological evolution, offering solutions that cater to both local and international markets.

Types of Quenching Systems and Media

Different metals and desired outcomes require different quenching methods and media. The main types include:

Water Quenching

- Cooling Rate: Fastest

- Applications: Carbon steels, high-strength components

- Advantages: Achieves maximum hardness

- Disadvantages: High risk of cracking and distortion due to thermal shock

Oil Quenching

- Cooling Rate: Moderate

- Applications: Alloy steels, aluminum parts

- Advantages: Balances hardness and toughness, reduces cracking risk

- Disadvantages: Fire hazard, slower than water, requires careful temperature control

Polymer Quenching

- Cooling Rate: Adjustable (between water and oil)

- Applications: Aluminum alloys, specialty steels, aerospace parts

- Advantages: Tunable cooling rates, less distortion, environmentally friendly

- Disadvantages: Higher cost, requires precise concentration control

Gas/Air Quenching

- Cooling Rate: Slowest

- Applications: Precision parts, tool steels, large components

- Advantages: Minimal distortion, suitable for parts with tight tolerances

- Disadvantages: Lower achievable hardness, requires specialized equipment

Each quenching system must be matched to the specific alloy, component geometry, and performance requirements. French manufacturers offer a wide range of systems to suit every industrial need.

Key Features to Consider When Choosing a Quenching System

When selecting a quenching system manufacturer or supplier, several factors must be considered to ensure optimal performance and long-term reliability:

- Type of Metals/Alloys Processed: Different metals require different quenching approaches and media.

- Required Cooling Rates and Uniformity: The system must deliver consistent cooling to avoid internal stresses and defects.

- System Automation and Control: Integration with PLCs and automated lines enhances efficiency and traceability.

- Energy Efficiency and Environmental Compliance: Modern systems minimize energy consumption and meet strict environmental standards.

- After-Sales Support and Customization: Reliable technical support and the ability to customize systems are crucial for OEMs.

- Global OEM Experience: Manufacturers with international export experience understand the needs of global partners and can provide tailored solutions.

Top Quenching System Manufacturers and Suppliers in France

France is home to several globally recognized quenching system manufacturers and suppliers. Below are the leading companies, their specialties, and what sets them apart:

ECM Technologies

Headquarters: Grenoble, France

Specialization: Industrial furnaces, oil quenching systems, vacuum heat treatment

Overview:

ECM Technologies is a world leader in industrial furnace manufacturing, with a strong presence in quenching technology. Their oil quenching furnace system, ECO, is designed for high-volume, high-performance applications, making it ideal for OEMs and large-scale manufacturers. ECM Technologies is known for its advanced automation, energy efficiency, and global reach, with 85% of its production exported worldwide.

Key Features:

- Advanced oil quenching for parts incompatible with gas quenching

- Customizable furnace designs for specific process requirements

- High export ratio, ensuring global service and support

CIMCOOL (DuBois Chemicals)

Headquarters: France (European division)

Specialization: Quenching fluids, both oil-based and water-based

Overview:

CIMCOOL, now part of DuBois Chemicals, offers a comprehensive range of quenching fluids engineered for European standards. Their portfolio includes oil-based and water-based quenchants, designed for intricate parts and high-hardenability alloys. CIMCOOL is renowned for its research-driven approach and commitment to sustainability.

Key Products:

- AAA-DA Quench Oil: Fast oil quenchant for a variety of steels

- 420-A Quench Oil: For high alloy, distortion-prone parts

- Alumiquench: Polymer quenchant for aluminum alloys, aerospace compliant

BMI Fours

Headquarters: France

Specialization: Custom-made industrial furnaces, including quenching systems

Overview:

BMI Fours designs and manufactures custom furnaces for heat treatment, including quenching systems tailored to the needs of the aeronautics and automotive sectors. Their expertise in custom solutions makes them a preferred partner for OEMs with unique requirements. BMI Fours is particularly strong in vacuum heat treatment and precision engineering.

GTM France SAS

Headquarters: France

Specialization: Induction heat treatment, gas furnaces, quenching and tempering lines

Overview:

GTM France SAS offers extensive heat treatment capabilities, including low-frequency induction lines for quenching, tempering, and annealing of long steel bars and tubes. Their gas furnaces support water or polymer quenching, with a focus on homogeneity and minimal deformation. GTM France SAS is known for its innovative approach to large-scale and continuous processing.

Key Features:

- Induction lines for steel bars up to 15 meters

- Gas furnaces for large-scale thermal treatment

- Real-time adjustment of treatment parameters

Thermi-Lyon Group

Headquarters: Lyon, France

Specialization: Contract heat treatment, vacuum deposition, large-part processing

Overview:

Thermi-Lyon is France's leading group in heat treatment and vacuum deposition, with a network of production sites and a strong focus on technological innovation. Their services include quenching of steel and light alloys, with expertise in both traditional and advanced processes. Thermi-Lyon is NADCAP-certified, making it a trusted partner for aerospace and high-tech industries.

Key Features:

- Multiple locations across France for local and international service

- Expertise in large-part processing (up to 1.5 tons per load)

- Advanced process control and quality assurance

Innovations and Trends in French Quenching Systems

French quenching system manufacturers and suppliers are at the forefront of technological innovation. Recent trends include:

Automation and Digitalization

Modern quenching systems are increasingly integrated with advanced automation and digital control. PLCs, SCADA systems, and IoT sensors enable real-time monitoring, precise process control, and data-driven optimization. This not only improves product quality but also enhances traceability and regulatory compliance.

Energy Efficiency and Sustainability

With growing environmental concerns, French manufacturers are investing in energy-efficient designs and eco-friendly quenching media. Polymer-based quenchants, closed-loop cooling systems, and heat recovery technologies are becoming standard features. These innovations help reduce operational costs and meet stringent environmental regulations.

Customization and Modular Design

OEMs and global manufacturers often require tailored solutions. French suppliers excel in providing modular, customizable quenching systems that can be adapted to specific production lines, part sizes, and process requirements. This flexibility is a key advantage for companies with diverse product portfolios.

Advanced Materials and Applications

The rise of high-performance alloys, lightweight materials, and complex geometries has driven the development of specialized quenching systems. French manufacturers are pioneering solutions for aerospace-grade aluminum, ultra-high-strength steels, and additive-manufactured components, ensuring optimal performance and reliability.

Case Study: Aluminum Quenching in France

Aluminum alloys are widely used in the automotive and aerospace industries due to their excellent strength-to-weight ratio. However, achieving the desired mechanical properties requires precise heat treatment and quenching.

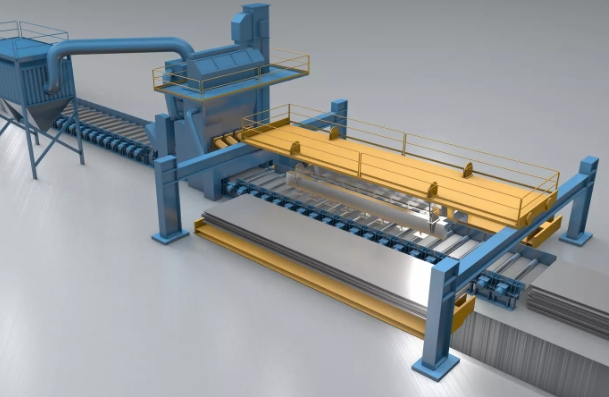

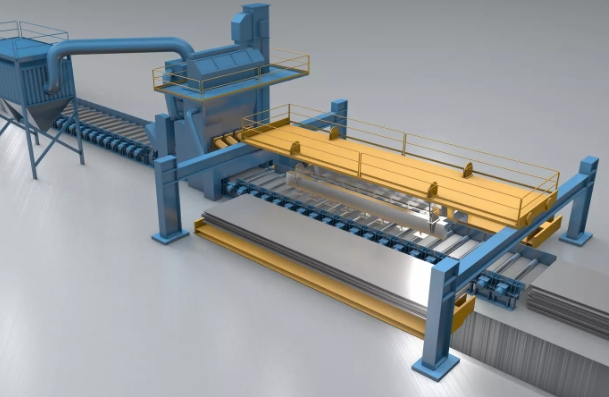

Drop-Bottom Furnace Technology

Drop-bottom furnaces are a hallmark of French innovation in aluminum quenching. These systems allow for rapid transfer of parts from the furnace to the quenching tank, minimizing quench delay and ensuring uniform properties. French manufacturers offer fully automatic and semi-automatic drop-bottom systems, integrating solution annealing, quenching, and artificial aging in a single line.

Benefits for OEMs and Exporters

- Short Quench Delay: Essential for T6 heat treatments and high-performance applications

- Process Consistency: Automated control ensures repeatable results

- Versatility: Suitable for thin-walled, complex, and large aluminum parts

French expertise in aluminum quenching makes its suppliers a top choice for international manufacturers seeking quality and reliability.

The Export Advantage: Why Choose French Suppliers?

French quenching system manufacturers and suppliers have a strong reputation for quality, innovation, and global service. Key advantages include:

- Proven Export Experience: Many French companies export the majority of their production, ensuring familiarity with international standards and logistics.

- Technical Expertise: French suppliers are known for their engineering excellence and ability to tackle complex projects.

- After-Sales Support: Comprehensive training, maintenance, and spare parts services are available worldwide.

- Compliance and Certification: French systems meet the highest industry standards, including ISO, NADCAP, and aerospace certifications.

- Customization: Solutions can be tailored to the unique needs of OEMs, wholesalers, and production partners.

For global brands and manufacturers, partnering with French quenching system suppliers ensures access to cutting-edge technology, robust quality assurance, and reliable long-term support.

Conclusion

The landscape of quenching system manufacturers and suppliers in France is characterized by technological innovation, engineering excellence, and a commitment to quality. Companies like ECM Technologies, CIMCOOL (DuBois Chemicals), BMI Fours, GTM France SAS, and Thermi-Lyon Group lead the way in providing advanced solutions for a wide range of industries.

French quenching systems offer unparalleled advantages in automation, energy efficiency, customization, and global service. Whether you are an OEM, wholesaler, or manufacturer seeking reliable partners for aluminum, steel, or specialty alloy processing, France's top suppliers are well-equipped to meet your needs.

By choosing a French quenching system manufacturer or supplier, you gain access to state-of-the-art technology, proven export expertise, and the assurance of consistent, high-quality results. As industries continue to evolve and demand ever-higher standards, French suppliers remain at the forefront, delivering solutions that drive progress and performance worldwide.

Frequently Asked Questions

1. What is the primary advantage of oil-based quenching systems?

Oil-based quenching provides a slower cooling rate than water, reducing the risk of cracking and distortion. This makes it suitable for alloy steels and parts requiring a balance between hardness and toughness.

2. Are polymer quenching systems suitable for aluminum alloys?

Yes, polymer quenching systems, such as Alumiquench, are specifically designed for solution heat treating a wide range of aluminum alloys and are compliant with aerospace specifications.

3. How do French quenching system manufacturers support global OEMs?

Leading French manufacturers like ECM Technologies and CIMCOOL have extensive export experience, offer customizable solutions, and provide technical support tailored to international standards and customer needs.

4. What safety considerations are important in quenching operations?

Safety concerns include the risk of burns from high temperatures, fire hazards with oil quenching, and potential health risks from chemical quenchants. Proper PPE, system design, and training are essential.

5. Can quenching systems be integrated with automated production lines?

Yes, many modern quenching systems feature PLC integration and can be fully automated for high-throughput, consistent, and traceable production.