Content Menu

● The Italian Puller Industry: An Overview

● The Importance of Pullers in Modern Industry

● Leading Puller Manufacturers And Suppliers in Italy

>> OMAC Italy

>>> Company Profile

>>> Key Products

>>> Technological Highlights

>>> OEM and Export Services

>> Tesmec S.p.A.

>>> Company Profile

>>> Key Products

>>> Technological Highlights

>>> OEM and Export Services

>> Galli S.p.A.

>>> Company Profile

>>> Key Products

>>> Technological Highlights

>>> OEM and Export Services

● Product Innovations and Technologies

● OEM Services and Global Reach

● Quality Assurance and Certifications

● Sustainability and Environmental Responsibility

● Customer Support and After-Sales Service

● Market Trends and Future Outlook

● Conclusion

● Frequently Asked Questions

>> 1. What industries do Italian puller manufacturers and suppliers serve?

>> 2. Can Italian puller manufacturers provide OEM services for international clients?

>> 3. What are the key technological features of Italian pullers?

>> 4. How do Italian puller manufacturers ensure product quality and safety?

>> 5. Are Italian pullers suitable for both overhead and underground cable applications?

Italy is renowned for its engineering prowess and industrial innovation, standing as a global leader in the production of specialized machinery. Among its many strengths, the country boasts a robust sector of puller manufacturers and suppliers, serving a diverse range of industries such as power transmission, cable laying, railway electrification, leather goods, and precision engineering. This article provides a comprehensive overview of the top puller manufacturers and suppliers in Italy, highlighting their products, technological advancements, and the value they bring to international OEM clients, wholesalers, and producers.

The Italian Puller Industry: An Overview

Italy's industrial machinery sector is characterized by a tradition of craftsmanship, continuous innovation, and a strong export orientation. Puller manufacturers and suppliers in Italy cater to a wide range of applications, including:

- Overhead and underground cable stringing

- Power transmission line construction

- Railway electrification

- Leather goods manufacturing

- Precision engineering and material handling

Italian puller manufacturers and suppliers are known for their ability to deliver customized solutions, advanced safety features, and reliable after-sales support, making them preferred partners for OEM clients worldwide.

The Importance of Pullers in Modern Industry

Pullers are essential machines used to install, tension, and maintain cables, wires, and other materials in various industrial settings. Their applications span:

- Power and Energy: Pullers are vital for stringing high-voltage power lines, ensuring efficient and safe installation.

- Telecommunications: Used for laying fiber optic and communication cables, supporting the expansion of modern networks.

- Railway Electrification: Pullers facilitate the installation of overhead catenary systems, crucial for electric trains.

- Manufacturing: In sectors like leather goods and precision engineering, pullers are integrated into automated production lines for material handling and processing.

The demand for advanced puller technology continues to grow as industries seek greater efficiency, safety, and automation.

Leading Puller Manufacturers And Suppliers in Italy

OMAC Italy

Company Profile

Founded in 1954 and headquartered in Chiuduno, Lombardia, OMAC Italy is a premier manufacturer specializing in high-performance pullers, tensioners, and stringing equipment for overhead, underground, and railway applications. With over 70 years of experience, OMAC Italy has become synonymous with innovation, safety, and reliability in the puller industry.

Key Products

- Hydraulic Pullers: Designed for both overhead and underground cable laying, with models offering maximum pull forces up to 240 kN.

- Puller-Tensioners: Versatile machines capable of both pulling and tensioning, ideal for complex stringing operations.

- Customized Solutions: OMAC Italy offers tailored equipment to meet specific project requirements, ensuring optimal performance and safety.

Technological Highlights

- Advanced digital control panels with real-time data display and USB data export

- Safety features such as hydraulic brakes, stabilizers, and remote control options

- Robust construction for durability in challenging environments

OEM and Export Services

OMAC Italy provides comprehensive OEM services, supporting international clients with custom branding, technical support, and global logistics.

Tesmec S.p.A.

Company Profile

Tesmec S.p.A., established in 1951, is a global leader in the design and manufacture of stringing equipment, including pullers, tensioners, and trenchers. With manufacturing facilities in Grassobbio, Endine Gaiano, and Sirone, Tesmec serves clients in the power transmission, railway, and infrastructure sectors.

Key Products

- Digital Stringing Machines: High-performance pullers with advanced electronic controls for precise operation.

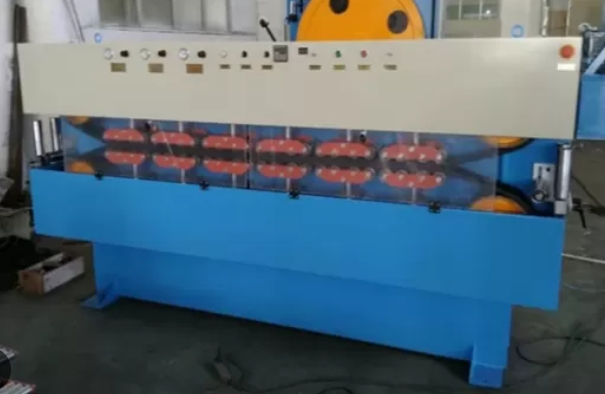

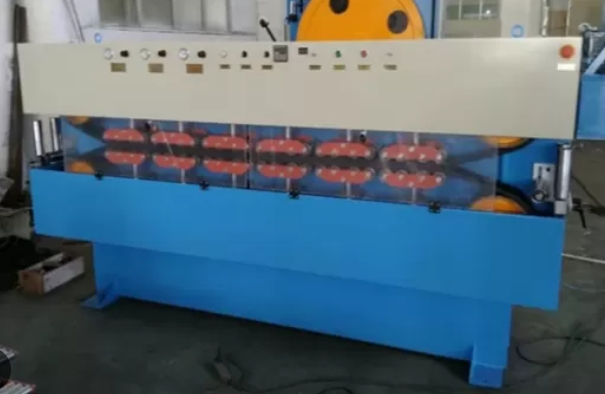

- Continuous Linear Pullers: Designed for efficient and safe reconductoring operations.

- Full Electric Machines: Environmentally friendly solutions with cutting-edge digital control and precision.

Technological Highlights

- Stepless speed variation and electronic pull pre-setting systems

- Remote control operation for enhanced safety and efficiency

- Integration with digital project management tools

OEM and Export Services

Tesmec offers OEM manufacturing, technical customization, and global distribution, making it a trusted partner for international puller manufacturers and suppliers.

Galli S.p.A.

Company Profile

Founded in 1979 in Vigevano, Galli S.p.A. is a leading designer and manufacturer of machinery for the leather goods industry. While primarily focused on leather processing, Galli's expertise in precision engineering and automation has positioned it as a key supplier of specialized pullers and related equipment for high-end manufacturing.

Key Products

- Leather Goods Machinery: Including punching, embossing, and cutting machines with integrated puller systems.

- Custom Automation Solutions: Tailored to the needs of luxury goods manufacturers, ensuring high precision and efficiency.

Technological Highlights

- Advanced CAD/CAM integration for custom machine design

- Full automation options for increased productivity

- Global customer support and training services

OEM and Export Services

Galli S.p.A. provides turnkey solutions, from individual machines to complete factory layouts, supporting OEM clients with customization and technical expertise.

Product Innovations and Technologies

Italian puller manufacturers and suppliers are at the forefront of technological innovation, offering features such as:

- Digital Control Panels: Real-time monitoring of pull force, speed, and cable length, with data export capabilities.

- Remote and Radio Controls: Allowing operators to manage machines from a safe distance, improving jobsite safety.

- Automatic Lubrication and Maintenance Systems: Extending machine life and reducing downtime.

- Customizable Attachments: For different cable types, conductor sizes, and jobsite conditions.

These innovations not only enhance operational efficiency but also ensure compliance with stringent safety standards, making Italian pullers highly sought after in global markets.

OEM Services and Global Reach

Italy's puller manufacturers and suppliers are highly experienced in serving international OEM clients, offering:

- Custom Branding and Design: Machines can be tailored to client specifications, including branding, color, and technical features.

- Comprehensive Support: From initial consultation and design to after-sales service and spare parts supply.

- Global Logistics: Efficient shipping and delivery to clients worldwide, supported by multilingual customer service teams.

This global approach has enabled Italian puller manufacturers and suppliers to establish long-term partnerships with leading brands, wholesalers, and producers across Europe, Asia, the Americas, and beyond.

Quality Assurance and Certifications

Italian puller manufacturers and suppliers adhere to rigorous quality assurance processes and hold internationally recognized certifications, such as ISO 9001 for quality management and CE marking for product safety. These certifications demonstrate a commitment to delivering reliable, high-quality products that meet the needs of demanding industrial applications.

Sustainability and Environmental Responsibility

Modern Italian puller manufacturers and suppliers are increasingly focused on sustainability, integrating eco-friendly practices into their production processes. This includes:

- Energy-Efficient Machinery: Development of electric and hybrid pullers to reduce emissions and energy consumption.

- Recyclable Materials: Use of recyclable and sustainable materials in machine construction.

- Waste Reduction: Implementation of lean manufacturing techniques to minimize waste and environmental impact.

By prioritizing sustainability, Italian manufacturers not only comply with global environmental standards but also contribute to a greener future for the industry.

Customer Support and After-Sales Service

A key strength of Italian puller manufacturers and suppliers is their commitment to customer satisfaction. Comprehensive after-sales services include:

- Technical Support: Expert assistance for installation, operation, and troubleshooting.

- Training Programs: On-site and remote training for operators and maintenance personnel.

- Spare Parts Availability: Fast and reliable supply of genuine spare parts to minimize downtime.

- Maintenance Contracts: Preventive maintenance services to ensure optimal machine performance.

These services help clients maximize the value of their investment and maintain high productivity levels.

Market Trends and Future Outlook

The global demand for advanced puller technology is expected to grow, driven by:

- Infrastructure Expansion: Ongoing investments in power grids, telecommunications, and transportation networks.

- Automation and Digitalization: Increasing adoption of smart technologies and Industry 4.0 solutions.

- Sustainability Initiatives: Rising demand for energy-efficient and environmentally friendly machinery.

Italian puller manufacturers and suppliers are well-positioned to capitalize on these trends, leveraging their expertise, innovation, and global reach to meet evolving market needs.

Conclusion

Italy's puller manufacturers and suppliers have established themselves as global leaders through a combination of technical excellence, innovation, and customer-centric services. Companies like OMAC Italy, Tesmec S.p.A., and Galli S.p.A. exemplify the strengths of the Italian industrial machinery sector, offering advanced products and comprehensive OEM solutions for clients worldwide. With a focus on quality, sustainability, and continuous improvement, Italian puller manufacturers and suppliers are poised to remain at the forefront of the industry, supporting the growth and modernization of critical infrastructure around the globe.

Frequently Asked Questions

1. What industries do Italian puller manufacturers and suppliers serve?

Italian puller manufacturers and suppliers cater to industries such as power transmission, telecommunications, railway electrification, leather goods manufacturing, and precision engineering.

2. Can Italian puller manufacturers provide OEM services for international clients?

Yes, leading Italian puller manufacturers and suppliers offer comprehensive OEM services, including custom branding, technical customization, and global logistics support.

3. What are the key technological features of Italian pullers?

Key features include digital control panels, remote and radio controls, automatic lubrication systems, and customizable attachments for various applications.

4. How do Italian puller manufacturers ensure product quality and safety?

Manufacturers adhere to strict quality standards, incorporate advanced safety features, and provide thorough after-sales support to ensure reliability and customer satisfaction.

5. Are Italian pullers suitable for both overhead and underground cable applications?

Yes, Italian puller manufacturers and suppliers design machines for both overhead and underground cable stringing, offering versatile solutions for diverse project needs.