Content Menu

● The Role and Functionality of Automatic Stackers

>> Core Features

>> Types of Automatic Stackers

● Advantages of Partnering With South Korean Suppliers

>> 1. Advanced Quality and Engineering

>> 2. Innovation and Smart Technology

>> 3. Strong Customization Capabilities

>> 4. Comprehensive After-Sales Support

>> 5. Global Traceability and Reputation

● Leading Automatic Stacker Manufacturers And Suppliers in South Korea

>> 1. Korea Crane Engineering (KCE)

>> 2. SMCore Inc.

>> 3. Han Tek Inc.

>> 4. INNOSY-M

>> 5. SFA

>> Other Major Players

● Technological Advancements and Trends

>> 1. Smart Integration

>> 2. Energy Efficiency

>> 3. Robotics and AI

>> 4. Enhanced Safety

>> 5. Modular Design

● Key Considerations When Selecting a Supplier

>> Technical Specifications

>> Customization and Flexibility

>> Reliability and Durability

>> Support and Training

>> Cost and ROI

● Common Industry Applications of Automatic Stackers

● OEM and Customization for the Global Market

● Challenges and the Future Outlook

>> Industry Challenges

>> Future Prospects

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of choosing South Korean Automatic Stacker Manufacturers And Suppliers for my business?

>> 2. Which industries benefit the most from Korean automatic stackers?

>> 3. Can South Korean suppliers provide OEM or customized stackers for overseas brands?

>> 4. How do automatic stackers contribute to operational safety?

>> 5. What support do South Korean stacker suppliers offer after purchase?

In the era of Industry 4.0, the drive toward automation and intelligent logistics has dramatically transformed material-handling processes across countless industries. At the heart of this revolution are automatic stackers—powerful and sophisticated machines designed to streamline storage, retrieval, and movement of materials with precision and safety. Nowhere is this innovation more advanced than in South Korea, home to some of the world's top Automatic Stacker Manufacturers And Suppliers. These companies serve global brands, wholesalers, and OEM partners, setting exceptional standards in quality, adaptability, and technological innovation.

This comprehensive article delves into the world of Automatic Stacker Manufacturers And Suppliers in South Korea, providing an in-depth look at market leaders, technological advancements, industry applications, and detailed guidance for international buyers. If your business needs a tailored, efficient, and dependable stacking solution, South Korea's manufacturers are sure to impress.

The Role and Functionality of Automatic Stackers

Automatic stackers are indispensable to modern material-handling, especially in environments where efficiency, throughput, and precision are paramount. At their core, stackers are automated machinery designed to stack, organize, transport, or retrieve various types of goods, boxes, or pallets within a warehouse, distribution center, or production facility. Their designs range from stand-alone units for smaller operations to highly-integrated stacker cranes developed for complex automated storage and retrieval systems (AS/RS).

Core Features

- Autonomous Operation: Using embedded sensors, PLCs, and software controls, these machines function with minimal human intervention.

- Flexibility: Suitable for transporting everything from lightweight electronics to heavy industrial goods.

- Scalability: Can be matched to both expansive warehouse networks or small-scale production facilities.

- Safety: Incorporate anti-collision systems, fail-safes, and real-time monitoring.

- Precision: Sophisticated controls enable precise stacking and extraction, minimizing product damage.

Types of Automatic Stackers

- Electric and Hydraulic Stackers: Widely used for varying load capacities, from small component trays to large industrial pallets.

- Stacker Cranes: Employed in high-bay warehouses, these are tall machines that travel along aisles to place or retrieve goods at various heights.

- AGV-Based Stackers: Automated Guided Vehicles fitted with stacking capabilities for enhanced mobility and flexible layouts.

- Specialized Stackers: Custom solutions for sectors like electronics, food processing, and automotive manufacturing.

Advantages of Partnering With South Korean Suppliers

South Korea's reputation as a high-tech industrial powerhouse is evident in its fast-growing automation sector. The following advantages are notable for businesses choosing Automatic Stacker Manufacturers And Suppliers from South Korea:

1. Advanced Quality and Engineering

Korean manufacturers implement rigorous quality controls and utilize state-of-the-art engineering standards. Their machines are often ISO-certified and comply with both regional and international regulations, such as CE and UL, giving buyers confidence in long-term operational reliability.

2. Innovation and Smart Technology

Many Korean suppliers are pioneers in smart warehouse systems, integrating real-time inventory management software, wireless connectivity, and data analytics, supporting businesses aiming to build intelligent, fully-automated logistics facilities.

3. Strong Customization Capabilities

Unlike many global regions offering standard products, South Korean companies go the extra mile in tailoring solutions. They can modify machine dimensions, payload specifications, control systems, and interfaces to meet virtually any industrial requirement.

4. Comprehensive After-Sales Support

With a robust infrastructure for international support, South Korean manufacturers provide extensive service packages—ranging from installation and commissioning, through to preventative maintenance, training, and parts replacement.

5. Global Traceability and Reputation

South Korea's best stacker suppliers are experienced in serving Fortune 500 manufacturers, global retail giants, and international electronics firms. This speaks volumes about their capacity to deliver dependable, scalable solutions worldwide.

Leading Automatic Stacker Manufacturers And Suppliers in South Korea

1. Korea Crane Engineering (KCE)

KCE is a trusted name in the world of cranes and advanced lifting mechanisms. Their range of stackers includes both manual and fully-automatic models, designed to support fast-paced logistics operations. KCE is notable for delivering solutions engineered to precise customer needs, covering everything from compact electric stackers to massive stacker cranes for high-bay storage facilities. Their engineering teams provide full turnkey services, from layout design to training.

2. SMCore Inc.

With decades of experience, SMCore is well-known for its highly efficient automated storage and retrieval systems—key to large, multi-level warehouses in Korea and around the world. Their automatic stackers are built with high-speed drive units, advanced navigation via laser and RFID, and integration-readiness for smart factory environments. SMCore's stackers can be found in facilities handling everything from automotive parts to high-tech semiconductors.

3. Han Tek Inc.

Han Tek Inc. specializes in AGV-based systems for materials movement and stacking. Their stackers feature advanced navigation and remote management, functioning reliably on busy production floors where adaptability is essential. Han Tek's commitment to innovation ensures that their solutions minimize labor costs and keep safety at the forefront.

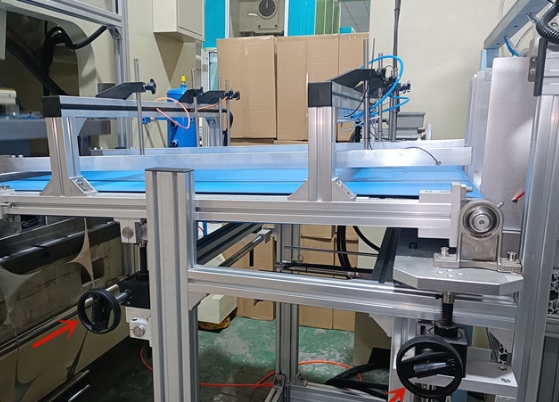

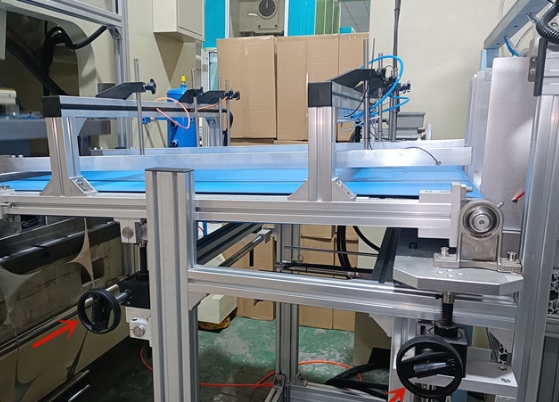

4. INNOSY-M

As South Korea's only dedicated automatic stacker manufacturer, INNOSY-M brings unrivaled focus to stacker design, manufacturing, and export. With a reputation for technical excellence and fast lead times, INNOSY-M frequently works as an OEM partner, delivering both branded and white-label machines for overseas clients in China, Japan, the US, and beyond.

5. SFA

SFA is an industrial automation leader supporting major logistics hubs, where fast, high-volume handling is mission critical. Their signature “bucket stacker cranes” are ideal for dense AS/RS environments, maximizing vertical storage and throughput in minimal ground space.

Other Major Players

Companies such as OM Korea, TAEJIN ENG, and HAEIN also round out Korea's formidable landscape of Automatic Stacker Manufacturers And Suppliers. These manufacturers deliver electric and manual stackers, heavy-duty forklifts, and specialty products for unique industrial demands.

Technological Advancements and Trends

South Korea's stacker sector is defined by rapid technological progress and continuous R&D. Several trends distinguish the country's Automatic Stacker Manufacturers And Suppliers from global competitors:

1. Smart Integration

As businesses digitize their warehouse operations, the integration of stackers with Warehouse Management Systems (WMS), ERP solutions, and IoT-based analytics tools has become a necessity. This enables data-driven decision making, predictive maintenance, and remote troubleshooting.

2. Energy Efficiency

South Korean companies deploy cutting-edge battery technology, regenerative braking, and lightweight components to reduce power consumption and operational costs.

3. Robotics and AI

Korean manufacturers actively experiment with robotics and machine learning. Some advanced stackers are equipped with AI-powered path planning, dynamic load optimization, and real-time route adjustment.

4. Enhanced Safety

The adoption of 3D lidar, advanced obstacle-recognition software, and multi-layered safety redundancies ensures not just regulatory compliance, but world-class workplace safety.

5. Modular Design

Stackers with modular components support rapid customization, parts exchange, and simplified scalability as businesses grow or reconfigure their operations.

Key Considerations When Selecting a Supplier

Choosing the right Automatic Stacker Manufacturers And Suppliers is pivotal for global buyers. The following criteria should be thoroughly evaluated to ensure success:

Technical Specifications

- Ensure the machine's load capacity, speed, and stacking height match your operational needs.

- Evaluate the degree of automation and available software compatibility.

Customization and Flexibility

- Ask whether the supplier can accommodate special dimensions, climate considerations, or process integration with existing workflows.

Reliability and Durability

- Seek out references and case studies proving the supplier's machines have stood the test of time in demanding environments.

Support and Training

- Confirm the availability of after-sales service, training programs, and remote diagnostic support.

Cost and ROI

- Assess the total cost of ownership—including delivery, installation, and ongoing maintenance—against potential efficiency gains and labor savings.

Common Industry Applications of Automatic Stackers

South Korea's Automatic Stacker Manufacturers And Suppliers cater to diverse industries:

- Automotive: Fast, repetitive storage/retrieval of heavy components, tires, and parts.

- Electronics: High-speed, gentle handling for fragile and precision components.

- Retail and E-commerce: Automated buffering and rapid order fulfillment in distribution centers.

- Food and Beverage: Sanitary, high-throughput storage and handling for packaged goods.

- Metals and Heavy Industry: Handling of coils, sheets, and heavy assemblies.

- Pharmaceuticals: Automated, traceable handling to reduce contamination and optimize regulatory compliance.

OEM and Customization for the Global Market

A unique strength of South Korean manufacturers lies in their willingness to engage in deep OEM partnerships. As a result, many international brands source automatic stackers either directly or under white-label agreements from Korea. This brings advanced Korean engineering and cost efficiencies directly to global markets.

Typical OEM and ODM customization options include:

- Logo and branding changes for resellers and distributors.

- Color schemes and surface treatments according to buyer requirements.

- Electrical engineering adjustments for local voltage/frequency standards.

- Language localization of control software and user interfaces.

- Special compliance certifications for different export markets.

South Korean suppliers also excel at developing pilot projects for large overseas clients, establishing test systems to validate performance in the buyer's plant before scaling up for mass rollout.

Challenges and the Future Outlook

While the future of South Korea's Automatic Stacker Manufacturers And Suppliers is bright, several challenges and opportunities shape the evolution of this industry:

Industry Challenges

- Rising Competition: As global manufacturers vie for market share, Korean suppliers must innovate constantly to maintain their competitive edge.

- Skilled Labor Shortage: As automation proliferates, highly skilled engineers and technicians are in increased demand for support and customization.

- Decarbonization Pressure: New requirements for sustainability and low-emissions manufacturing affect both supplier operations and product design.

Future Prospects

- Expanding Exports: Korea's stacker manufacturers are increasingly focusing on emerging economies—particularly Southeast Asia, the Middle East, and South America.

- Integration of AI and Robotics: Look for even smarter systems, predictive analytics, and near-human levels of operational flexibility in next-generation stackers.

- Green Engineering: Suppliers are developing machines optimized for low energy consumption and recyclable materials, helping buyers meet ESG targets.

Conclusion

South Korea's Automatic Stacker Manufacturers And Suppliers have earned global recognition for delivering technologically advanced, reliable, and fully customizable solutions for modern material handling and logistics. By blending innovation with customer-centric service, Korean companies empower industries worldwide to achieve greater productivity, safety, and operational excellence. Whether you are an OEM brand looking for a trusted manufacturing partner or a production manager needing a state-of-the-art stacking solution, South Korea offers a wealth of expertise, experience, and partnership opportunities.

Frequently Asked Questions (FAQ)

1. What are the main advantages of choosing South Korean Automatic Stacker Manufacturers And Suppliers for my business?

Answer: South Korean suppliers offer advanced engineering, custom-tailored solutions, reliable after-sales support, and competitive pricing. Their experience with international brands ensures seamless integration and quality.

2. Which industries benefit the most from Korean automatic stackers?

Answer: Industries such as automotive, electronics, e-commerce, pharmaceuticals, food and beverage, and heavy industry benefit greatly from the efficiency, safety, and precision of Korean automatic stackers.

3. Can South Korean suppliers provide OEM or customized stackers for overseas brands?

Answer: Yes, many Korean manufacturers specialize in OEM/ODM production, delivering branded or customized stackers according to client specifications, including international compliance, design, and software needs.

4. How do automatic stackers contribute to operational safety?

Answer: Automatic stackers reduce workplace accidents through advanced sensors, collision-avoidance systems, and safety interlocks, limiting human intervention in potentially hazardous handling operations.

5. What support do South Korean stacker suppliers offer after purchase?

Answer: Most leading suppliers provide comprehensive services such as installation, system integration, operator training, preventive maintenance, and access to parts and software updates.