Content Menu

● What is an Automatic Stacker?

● Key Benefits of Automatic Stackers

● Top Automatic Stacker Manufacturers And Suppliers in America

>> 1. The Raymond Corporation

>> 2. Hyster-Yale Group, Inc.

>> 3. Vestil Manufacturing Corp.

>> 4. A.G. Stacker Inc.

>> 5. Bastian Solutions

>> 6. Erie Technical Systems Inc.

>> 7. UNI-PAK Corp.

>> 8. Meyer Material Handling Products, Inc.

>> 9. Wesco Industrial Products

>> 10. American Surplus, Inc.

● How to Choose the Right Automatic Stacker Manufacturer or Supplier

● Applications of Automatic Stackers

● Future Trends in Automatic Stacker Technology

● Conclusion

● Frequently Asked Questions

>> 1. What are the main advantages of using automatic stackers over manual stackers?

>> 2. Can automatic stackers be integrated with existing warehouse systems?

>> 3. How do I maintain an automatic stacker?

>> 4. Are there automatic stackers suitable for small warehouses?

>> 5. What safety features should I look for in an automatic stacker?

In the rapidly evolving world of logistics and material handling, automatic stackers have become essential equipment for warehouses, manufacturing plants, and distribution centers. These machines streamline the stacking and handling of pallets, boxes, sheets, and other materials, significantly boosting productivity and safety. As demand for automation grows, so does the need to identify the leading Automatic Stacker Manufacturers And Suppliers in America. This comprehensive article explores the top manufacturers, their innovations, applications, and what sets them apart in the competitive landscape.

What is an Automatic Stacker?

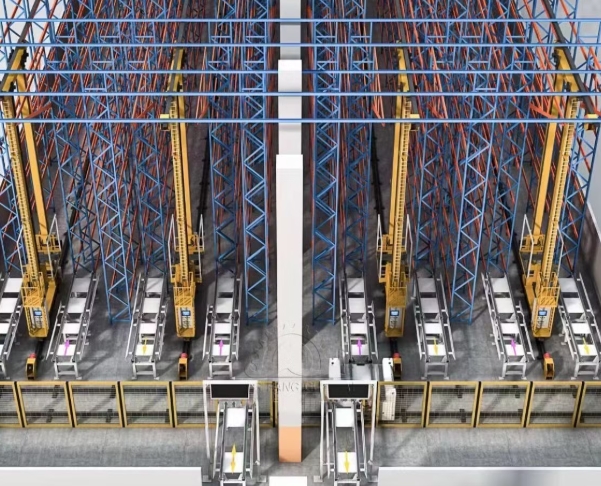

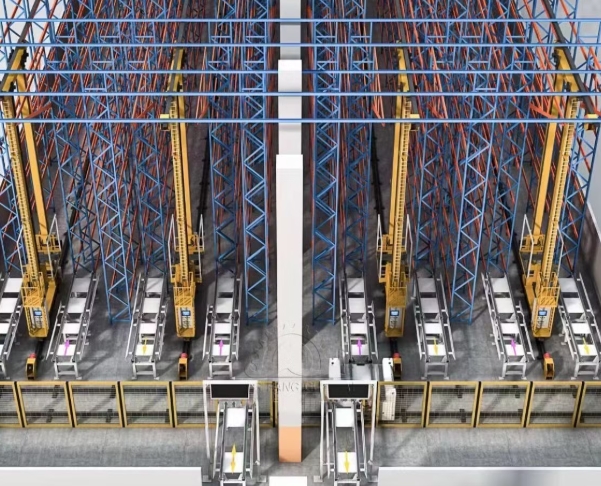

An automatic stacker is a machine designed to automate the process of stacking, transporting, and organizing materials such as pallets, boxes, or sheets in industrial settings. Unlike manual or semi-automatic stackers, automatic stackers are equipped with advanced sensors, programmable logic controllers (PLCs), and sometimes robotic arms, enabling them to operate with minimal human intervention. They are crucial for optimizing warehouse efficiency and ensuring consistent, safe material handling.

Automatic stackers can vary widely in design and complexity, from simple electric pallet stackers to fully integrated robotic systems capable of handling multiple product types. Their versatility allows them to be tailored to specific industry needs, whether it's stacking heavy pallets in a manufacturing plant or delicate cartons in a pharmaceutical warehouse.

Key Benefits of Automatic Stackers

- Increased Efficiency: Automatic stackers can operate continuously, reducing downtime and manual labor requirements. This leads to faster throughput and better utilization of warehouse space.

- Enhanced Safety: Automation minimizes the risk of workplace injuries associated with manual stacking, such as strains, falls, or collisions. Many automatic stackers come equipped with safety sensors and emergency stop features.

- Space Optimization: Precise stacking maximizes storage density in warehouses, allowing businesses to store more goods in less space.

- Consistency: Automated systems deliver uniform stacking, reducing product damage and improving overall quality control.

- Integration: Modern stackers can be integrated with warehouse management systems (WMS) and other automation tools for real-time tracking and inventory control, enabling smarter logistics operations.

- Cost Savings: While the initial investment may be significant, automatic stackers reduce labor costs and operational inefficiencies, providing a strong return on investment over time.

Top Automatic Stacker Manufacturers And Suppliers in America

In the competitive American market, several manufacturers and suppliers stand out for their innovation, quality, and customer service. Below is an in-depth look at the top 10 companies leading the industry.

1. The Raymond Corporation

Location: New York, USA

Overview:

Raymond is a pioneer in material handling solutions, offering a wide range of electric stackers and automated systems. Their stackers are known for durability, energy efficiency, and advanced safety features, making them a top choice for warehouses and distribution centers seeking reliable automation.

Key Products:

- Electric pallet stackers with ergonomic designs

- Automated guided vehicles (AGVs) that integrate with warehouse systems

- Customizable stacker solutions tailored to specific operational needs

Raymond's commitment to innovation is reflected in their continuous development of energy-efficient batteries and intelligent control systems, ensuring their products meet the demands of modern logistics.

2. Hyster-Yale Group, Inc.

Location: Ohio, USA

Overview:

Operating under the HYSTER and YALE brands, Hyster-Yale is a global leader in lift trucks and stackers. Their automated stackers are designed for heavy-duty applications and are widely used in ports, mining, and warehousing.

Key Products:

- Counterbalanced stackers capable of handling heavy loads

- Walkie stackers for narrow aisle operations

- Automated material handling systems with integrated safety and control features

Hyster-Yale emphasizes rugged construction and operator comfort, making their stackers suitable for demanding environments.

3. Vestil Manufacturing Corp.

Location: Michigan, USA

Overview:

Vestil manufactures a broad range of material handling equipment, including powered and manual stackers. Their products are known for ergonomic design and adaptability across industries such as manufacturing, construction, and logistics.

Key Products:

- Electric stackers with variable lift heights

- Hydraulic stackers for precise load handling

- Custom stacker solutions designed to meet specialized requirements

Vestil's focus on quality and innovation ensures their stackers deliver reliable performance in diverse industrial applications.

4. A.G. Stacker Inc.

Location: Virginia, USA

Overview:

A.G. Stacker specializes in custom manufacturing of industrial machinery for corrugated material stacking and handling. The company is renowned for its innovative, full-line solutions and commitment to service, offering 24/7 support and advanced digital technologies for factory simulation and planning.

Key Products:

- Corrugated material stackers designed for high-speed production lines

- Automated load formers that improve stacking accuracy and speed

- Digital twin systems that simulate factory operations for optimization

A.G. Stacker's unique combination of custom engineering and digital innovation positions them as a leader in corrugated material handling.

5. Bastian Solutions

Location: Indiana, USA

Overview:

Bastian Solutions is a leading integrator and manufacturer of automated pallet stackers and dispensers. Their solutions are tailored for robotic and conventional palletizing systems, enhancing productivity and operational efficiency in various industries.

Key Products:

- Automated pallet stackers with robotic integration

- Pallet dispensers that improve material flow

- Integrated robotic systems designed for scalability

Bastian Solutions is known for its comprehensive approach, combining hardware, software, and system integration.

6. Erie Technical Systems Inc.

Location: Pennsylvania, USA

Overview:

Erie Technical Systems manufactures standard and custom automatic pallet stackers, focusing on robust construction and flexibility. Their PalletMAX™ system can be integrated into new or existing conveyor lines, offering fast stacking cycles and customizable options for different pallet sizes.

Key Products:

- PalletMAX™ automatic stackers with high throughput

- Conveyor-integrated stackers for seamless material flow

- Custom material handling solutions tailored to client needs

Erie Technical Systems prides itself on engineering excellence and responsive customer service.

7. UNI-PAK Corp.

Location: USA

Overview:

UNI-PAK is a custom manufacturer of automatic pallet stackers for industries such as automotive, electronics, food processing, and pharmaceuticals. Their products meet rigorous industry standards and are known for reliability and compliance.

Key Products:

- Automatic pallet stackers designed for cleanroom and controlled environments

- Custom stacking solutions that comply with industry regulations

UNI-PAK's expertise in regulated industries makes them a trusted partner for companies requiring high standards.

8. Meyer Material Handling Products, Inc.

Location: Indiana, USA

Overview:

Meyer is a distributor and custom manufacturer of hydraulic and battery-powered pallet stackers. Their solutions cater to diverse industry needs, offering both standard and customized stacker options.

Key Products:

- Hydraulic pallet stackers with precise control

- Battery-powered stackers designed for extended operation

Meyer emphasizes flexibility and customer-centric solutions.

9. Wesco Industrial Products

Location: Pennsylvania, USA

Overview:

Wesco offers a comprehensive range of manual, semi-electric, and fully powered stackers. Their products are widely used in warehouses, retail, and manufacturing for efficient material handling.

Key Products:

- Manual lift stackers for light-duty applications

- Power lift stackers with electric drive

- Fully powered stackers for heavy loads

Wesco's broad product line makes them accessible to a variety of customers.

10. American Surplus, Inc.

Location: Rhode Island, USA

Overview:

American Surplus is a major distributor of new and used electric stackers. They provide cost-effective solutions for businesses looking to automate their material handling processes without significant capital investment.

Key Products:

- Electric stackers suitable for various load types

- Straddle lifts and walkie stackers for versatile use

American Surplus offers competitive pricing and flexible purchasing options.

How to Choose the Right Automatic Stacker Manufacturer or Supplier

Selecting the ideal Automatic Stacker Manufacturers And Suppliers requires careful consideration of several factors:

- Product Range: Ensure the supplier offers stackers suitable for your specific application (pallets, sheets, boxes, etc.). Some manufacturers specialize in certain industries or materials.

- Customization: Look for manufacturers who can tailor solutions to your operational needs, including size, load capacity, and integration with existing systems.

- After-Sales Support: Strong technical support and readily available spare parts are crucial for minimizing downtime. Consider suppliers with 24/7 customer service.

- Compliance: Verify that products meet industry standards such as OSHA, ANSI, and UL to ensure safety and reliability.

- Integration: Consider stackers that can integrate with your existing warehouse management systems and automation infrastructure.

- Reputation: Choose companies with proven track records, positive customer feedback, and a history of innovation.

- Cost and ROI: Evaluate the total cost of ownership, including purchase price, maintenance, and operational savings.

Applications of Automatic Stackers

Automatic stackers are versatile and find applications in a wide range of industries:

- Warehousing & Distribution: For palletizing, depalletizing, and inventory management, automatic stackers reduce manual labor and increase throughput.

- Manufacturing: To move materials between production lines and storage, ensuring smooth workflow and timely delivery.

- Food & Beverage: For handling packaged goods and raw materials safely, maintaining hygiene standards.

- Pharmaceuticals: Ensuring hygienic and precise material handling in controlled environments.

- Automotive: For stacking heavy components and assemblies, improving safety and efficiency.

- Retail: Streamlining backroom logistics and stock replenishment, especially in large retail chains.

- Corrugated and Packaging Industry: Specialized stackers handle sheets and boxes with precision, reducing damage and increasing speed.

Future Trends in Automatic Stacker Technology

The landscape of Automatic Stacker Manufacturers And Suppliers is rapidly changing, driven by technological advancements:

- Robotic Integration: Increasing use of collaborative robots (cobots) for flexible stacking and load forming. These robots can adapt to different products and layouts, offering unparalleled versatility.

- IoT & Smart Warehousing: Stackers equipped with sensors and connectivity enable real-time monitoring, predictive maintenance, and data analytics to optimize operations.

- Energy Efficiency: Adoption of lithium-ion batteries and regenerative braking systems reduces energy consumption and extends operational time.

- Customization and Modularity: Modular designs allow for easy upgrades and reconfiguration, enabling businesses to adapt quickly to changing demands.

- Safety Enhancements: Advanced safety features such as obstacle detection, emergency stops, remote diagnostics, and AI-based hazard prediction improve workplace safety.

- AI and Machine Learning: Integration of AI algorithms for optimizing stacking patterns, load balancing, and autonomous navigation.

- Sustainability: Manufacturers are focusing on eco-friendly materials and processes to reduce environmental impact.

Conclusion

The demand for efficient, safe, and reliable material handling solutions has made automatic stackers indispensable in modern warehouses and manufacturing facilities. America hosts a robust ecosystem of Automatic Stacker Manufacturers And Suppliers that cater to diverse industries with innovative, customizable, and high-quality products.

From industry giants like The Raymond Corporation and Hyster-Yale Group to specialized innovators such as A.G. Stacker Inc. and Erie Technical Systems, these manufacturers provide a wide spectrum of solutions that address the evolving needs of automation and logistics.

When choosing a supplier, businesses should consider product range, customization capabilities, after-sales support, compliance, and integration potential to ensure the best fit. Looking ahead, advancements in robotics, IoT, AI, and energy efficiency will continue to transform the automatic stacker market, offering unprecedented opportunities for operational excellence.

By partnering with the right Automatic Stacker Manufacturers And Suppliers, companies can achieve significant improvements in productivity, safety, and cost savings, positioning themselves for success in the competitive global marketplace.

Frequently Asked Questions

1. What are the main advantages of using automatic stackers over manual stackers?

Automatic stackers offer increased efficiency, improved safety, and greater consistency in material handling. They reduce labor costs and the risk of workplace injuries, and can operate continuously with minimal supervision.

2. Can automatic stackers be integrated with existing warehouse systems?

Yes, most modern automatic stackers are designed for seamless integration with warehouse management systems (WMS) and other automation technologies, enabling real-time tracking and optimization of workflows.

3. How do I maintain an automatic stacker?

Regular maintenance includes checking battery levels, inspecting sensors and safety features, lubricating moving parts, and updating software. Many manufacturers offer preventive maintenance contracts and 24/7 technical support.

4. Are there automatic stackers suitable for small warehouses?

Absolutely. Many manufacturers offer compact models designed for tight spaces and lower throughput environments, making them ideal for small warehouses and retail backrooms.

5. What safety features should I look for in an automatic stacker?

Key safety features include obstacle detection, emergency stop buttons, load sensors, and compliance with industry safety standards such as OSHA and ANSI.