Content Menu

● Understanding Aluminum Extrusion Presses

● Why South Korea Leads in Aluminum Extrusion Press Manufacturing

>> Advanced Manufacturing Excellence

>> Strict Regulatory Environment

>> Culture of Innovation

>> Global Reach and Export Expertise

● Top Aluminum Extrusion Press Manufacturers and Suppliers in South Korea

>> 1. SKM (SKM Korea)

>> 2. Sunwoo Engineering

>> 3. Changwon Precision Extrusions (Now part of SeAH Besteel Corporation)

>> 4. HAI Materials Korea (HAIMK) – Hammerer Aluminium Industries & LS Cable & System

>> 5. ALUS Co., Ltd.

>> 6. DH Global

>> 7. Jinwoo Metal Co., Ltd.

>> 8. SEAH Aerospace Defense Co., ALUTEC Co. Ltd., Hanyang Light Metal Co. Ltd.

● Technological Innovations and Industry Trends

>> Automation and Smart Manufacturing

>> Hybrid Drive Systems

>> Precision Engineering and Customization

>> Sustainability and Environmental Responsibility

● Industry Applications of Aluminum Extrusion Presses

● How to Choose the Right Aluminum Extrusion Press Manufacturer or Supplier

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of sourcing aluminum extrusion presses from South Korea?

>> 2. Which industries most commonly use aluminum extrusion presses?

>> 3. What are the latest technological trends in aluminum extrusion presses?

>> 4. How do South Korean suppliers ensure product quality?

>> 5. Can South Korean manufacturers provide custom alloyed billets and profiles?

South Korea has emerged as a global leader in the aluminum extrusion industry, distinguished by its advanced manufacturing technologies, stringent quality standards, and relentless pursuit of innovation. As industries worldwide—ranging from automotive and aerospace to construction and renewable energy—seek lightweight, durable, and high-performance materials, South Korean aluminum extrusion press manufacturers and suppliers have become increasingly sought after. This article provides an in-depth look at the top companies in the sector, their technological strengths, and the evolving landscape of aluminum extrusion press manufacturing in South Korea.

Understanding Aluminum Extrusion Presses

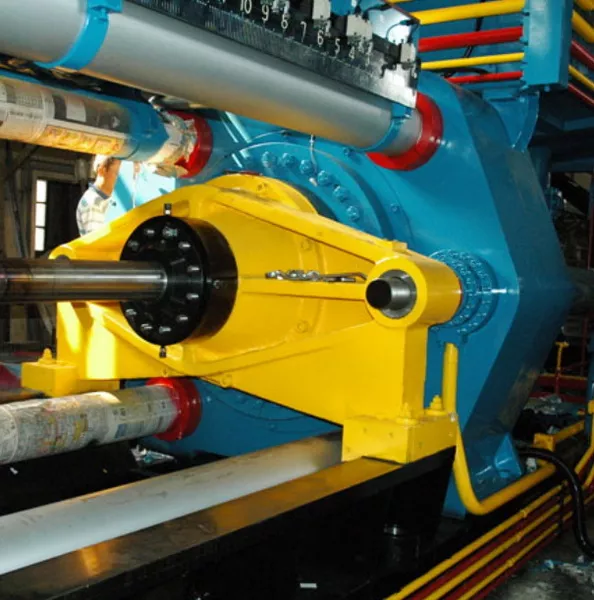

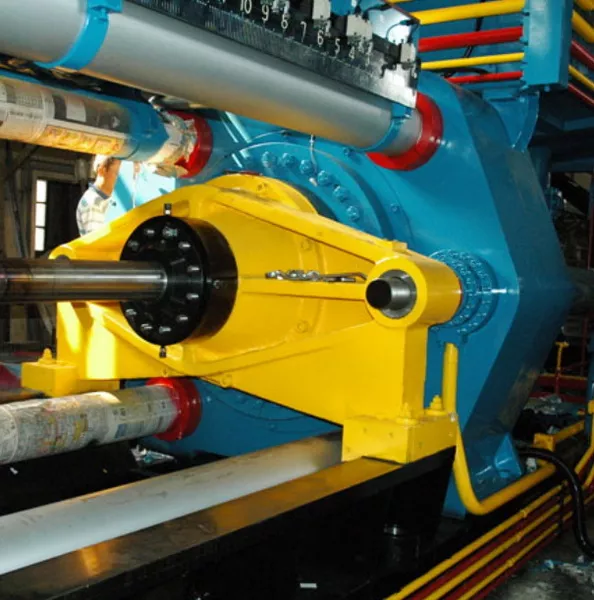

Aluminum extrusion presses are specialized machines that shape heated aluminum billets into profiles with specific cross-sections by forcing them through a die. These presses are fundamental to producing components for a wide array of industries, including automotive, aerospace, electronics, construction, and renewable energy. South Korean manufacturers have mastered both direct and indirect extrusion technologies, emphasizing energy efficiency, precision, and automation in their solutions.

Why South Korea Leads in Aluminum Extrusion Press Manufacturing

Advanced Manufacturing Excellence

South Korea's reputation for high-quality production is underpinned by continuous investment in research and development. Manufacturers in the country employ state-of-the-art machinery, lean manufacturing processes, and rigorous quality control systems to ensure that every extrusion press meets or exceeds international standards.

Strict Regulatory Environment

The South Korean government enforces some of the world's most stringent environmental and safety regulations. This commitment to responsible manufacturing ensures that South Korean aluminum extrusion press manufacturers and suppliers operate sustainably, with a focus on reducing emissions, conserving resources, and maintaining workplace safety.

Culture of Innovation

Innovation is at the heart of South Korea's industrial success. Companies continually introduce new technologies—such as hybrid drive systems, automated quality control, and advanced die design—to improve efficiency, reduce waste, and enhance product quality.

Global Reach and Export Expertise

South Korean manufacturers and suppliers serve not only the domestic market but also a vast international clientele. Their experience with global logistics, export documentation, and compliance with international standards makes them reliable partners for OEMs, wholesalers, and production companies worldwide.

Top Aluminum Extrusion Press Manufacturers and Suppliers in South Korea

1. SKM (SKM Korea)

SKM is a pioneer in aluminum extrusion press technology in South Korea. As the first Korean company to develop the Front Loading Type Extrusion Press, SKM has set industry benchmarks for innovation and performance. The company collaborates closely with academic institutions, such as INHA University, to ensure structural stability and optimized design in their presses.

Key Strengths:

- Development of the Front Loading Type Extrusion Press (first in Korea)

- Advanced R&D partnerships with universities

- High-performance, precision-engineered presses

- Capability to deliver extrusion equipment up to 8,500 tons

- Complete line of extrusion processing manufacturing facilities

Product Range:

- Aluminum Extrusion Presses

- Copper and Brass Extrusion Presses

- Die Casting Equipment

- Handling Equipment

- Anodizing Plants

SKM's presses are trusted by industries requiring high-precision aluminum profiles, including construction, transportation, and industrial machinery.

2. Sunwoo Engineering

Sunwoo Engineering is renowned for its expertise in manufacturing extrusion and handling facilities for aluminum, magnesium, and copper alloys. The company's presses are designed with robust frames, energy-saving systems, and advanced quality control technologies.

Key Strengths:

- Direct, Indirect, and Tube Extrusion Presses

- Compact hydraulic drive systems for space and energy efficiency

- Hybrid systems that reduce energy consumption

- Vision sensor systems for real-time quality monitoring

- Structural analysis for optimal frame design

Sunwoo Engineering's solutions are widely adopted in the automotive, electronics, and heavy industries, where high-strength and precision components are essential.

3. Changwon Precision Extrusions (Now part of SeAH Besteel Corporation)

Changwon Precision Extrusions, now integrated into SeAH Besteel Corporation, is a leading provider of hard alloy aluminum extruded products. The company's expertise spans aluminum casting, extrusion, heat treatment, and downstream processing, serving both Korean and international OEMs and Tier 1 customers.

Key Strengths:

- Specialized in hard alloy aluminum extrusion

- Comprehensive manufacturing capabilities from casting to finishing

- Strong presence in aerospace, defense, automotive, and industrial sectors

Changwon's integration with SeAH Besteel has further expanded its technological capabilities and market reach.

4. HAI Materials Korea (HAIMK) – Hammerer Aluminium Industries & LS Cable & System

HAIMK is a joint venture between Hammerer Aluminium Industries (HAI) and LS Cable & System, representing a significant investment in South Korea's aluminum extrusion industry. The company's facility in Gumi is equipped with a fully automated extrusion line featuring a pressing force of 60 meganewtons.

Key Strengths:

- 13,800 m² facility with state-of-the-art automation

- Pressing force of 60 MN for large and complex profiles

- Integrated upstream and downstream processing systems

- Focus on electromobility and advanced aluminum components

HAIMK's advanced manufacturing processes support the production of high-performance components for automotive, electromobility, construction, and industrial applications.

5. ALUS Co., Ltd.

ALUS is a premier aluminum extruder in Korea, known for its wide range of 6000 Series aluminum casting alloys suitable for extrusion presses. Operating two presses (7” and 12”), the company is recognized for its reliability and versatility in fulfilling large-scale orders.

Key Strengths:

- Modern aluminum foundry with a capacity of up to 36,000 MT annually

- Specialization in custom alloyed billets for extrusion presses

- Leading supplier of aluminum formwork for construction

ALUS serves a diverse customer base in building and construction, transportation, electrical, machinery, and consumer goods sectors.

6. DH Global

DH Global is a key supplier of piping materials and aluminum extrusions for the oil & gas, petrochemical, and power plant industries. The company's expertise in global sourcing and supply, combined with South Korea's advanced manufacturing standards, makes it a trusted partner for heavy industry projects.

Key Strengths:

- Extensive global sourcing and supply network

- Focus on heavy industry and energy sectors

- Compliance with stringent environmental and safety regulations

7. Jinwoo Metal Co., Ltd.

Jinwoo Metal operates a large aluminum extrusion factory in Gimpo, specializing in the mass production of aluminum pipes and profiles. The company's manufacturing processes are characterized by efficiency, consistency, and a commitment to quality.

8. SEAH Aerospace Defense Co., ALUTEC Co. Ltd., Hanyang Light Metal Co. Ltd.

According to export data, these companies are among the top aluminum extrusions suppliers in South Korea. SEAH Aerospace Defense Co. leads the market share, followed by ALUTEC and Hanyang Light Metal, each contributing significantly to the country's export strength.

Technological Innovations and Industry Trends

Automation and Smart Manufacturing

South Korean manufacturers are at the forefront of adopting automation in aluminum extrusion press operations. Fully automated extrusion lines, such as those at HAIMK, are setting new standards for efficiency, consistency, and quality control. Automated material handling, billet loading, and real-time monitoring systems minimize human error and maximize productivity.

Hybrid Drive Systems

Innovations like the HybrEx® press, featuring hybrid drive concepts, have revolutionized energy efficiency in extrusion presses. By combining hydraulic and electric drives, these systems can reduce energy consumption by up to 55% and increase productivity by 20%, making them highly attractive for environmentally conscious manufacturers.

Precision Engineering and Customization

South Korean manufacturers excel in producing custom alloyed billets and precision-engineered profiles. Advanced die design, computer-aided manufacturing, and close collaboration with customers enable the production of complex, high-performance components for demanding applications such as aerospace and electromobility.

Sustainability and Environmental Responsibility

A strong commitment to sustainability underpins the South Korean aluminum extrusion industry. Manufacturers invest in energy-saving systems, recycling initiatives, and eco-friendly production practices. Compliance with both domestic and international environmental regulations is a top priority, ensuring that production processes are as green as possible.

Industry Applications of Aluminum Extrusion Presses

Aluminum extrusion presses and the profiles they produce are vital to a broad range of industries:

- Automotive: Used for lightweight frames, battery trays, and structural components that improve fuel efficiency and safety.

- Aerospace: Essential for manufacturing high-strength, precision extrusions for aircraft structures and components.

- Construction: Widely used in window frames, curtain walls, scaffolding, and formwork systems.

- Electronics: Integral to the production of heat sinks, housings, connectors, and other components requiring excellent thermal and electrical conductivity.

- Renewable Energy: Key to the fabrication of solar panel frames, wind turbine components, and other green energy infrastructure.

How to Choose the Right Aluminum Extrusion Press Manufacturer or Supplier

When selecting an aluminum extrusion press manufacturer or supplier in South Korea, consider the following factors:

- Production Capacity: Assess whether the supplier can meet your required volume and profile size.

- Technological Capabilities: Look for advanced automation, hybrid drive systems, and state-of-the-art quality control.

- Customization: Ensure the manufacturer can provide custom alloyed billets and profiles tailored to your specifications.

- Export Experience: Choose suppliers with a proven track record in international markets and familiarity with global logistics.

- Sustainability: Prioritize companies committed to eco-friendly manufacturing and compliance with environmental regulations.

Conclusion

South Korea's aluminum extrusion press manufacturers and suppliers are global leaders, combining advanced technology, rigorous quality standards, and a forward-thinking approach to sustainability and innovation. Whether you are an OEM, wholesaler, or production company seeking high-performance extrusion solutions, South Korean companies offer a compelling mix of reliability, customization, and export expertise. By partnering with these industry leaders, you can ensure access to world-class aluminum extrusion presses and profiles that meet the demands of today's most challenging applications.

Frequently Asked Questions (FAQ)

1. What are the main advantages of sourcing aluminum extrusion presses from South Korea?

South Korean manufacturers offer advanced technology, strict quality control, and a strong focus on sustainability, making them reliable partners for global OEMs and industrial clients.

2. Which industries most commonly use aluminum extrusion presses?

Automotive, aerospace, construction, electronics, and renewable energy sectors are the primary users of aluminum extrusion presses and profiles.

3. What are the latest technological trends in aluminum extrusion presses?

Automation, hybrid drive systems for energy efficiency, and precision engineering for complex profiles are the leading trends.

4. How do South Korean suppliers ensure product quality?

Through rigorous R&D, collaboration with academic institutions, advanced quality control systems, and compliance with international standards.

5. Can South Korean manufacturers provide custom alloyed billets and profiles?

Yes, companies like ALUS and others specialize in producing custom alloys and tailored profiles to meet specific customer requirements.