Content Menu

● Understanding Aluminum Extrusion

● The Aluminum Extrusion Process: Step by Step

>> 1. Billet Preparation

>> 2. Loading and Lubrication

>> 3. Extrusion

>> 4. Quenching

>> 5. Cutting and Stretching

>> 6. Aging and Finishing

● Key Aluminum Extrusion Press Manufacturers and Suppliers in France

>> Exlabesa Flandria

>> Aluminium France Extrusion

>> Constellium

>> Profils Systèmes

>> Hydro Aluminium Extrusion Services S.A.

>> Sapa Extrusion France

>> Other Notable Suppliers

● OEM and Custom Manufacturing Capabilities

● Industry Trends and Innovations

>> 1. Sustainability and Low-Carbon Aluminum

>> 2. Digitalization and Automation

>> 3. Advanced Alloys and Lightweighting

>> 4. Customization and Design Flexibility

>> 5. Globalization and Export Growth

● Why Choose French Aluminum Extrusion Press Manufacturers and Suppliers?

● Conclusion

● Frequently Asked Questions (FAQ)

>> Q1: What is the aluminum extrusion process, and why is it important?

>> Q2: Which industries benefit most from aluminum extrusions?

>> Q3: Can French manufacturers provide OEM and custom extrusion services?

>> Q4: How do French suppliers ensure product quality and sustainability?

>> Q5: What are the main advantages of sourcing aluminum extrusions from France?

Aluminum extrusion has become a cornerstone of modern manufacturing, providing the backbone for countless products and structures across industries. France, with its advanced industrial base and strong engineering tradition, is home to some of the most reputable aluminum extrusion press manufacturers and suppliers in Europe. These companies not only serve the domestic market but also export high-quality aluminum profiles and extrusion machinery worldwide, supporting OEMs, wholesalers, and manufacturers in a broad array of sectors.

This comprehensive guide explores the leading aluminum extrusion press manufacturers and suppliers in France, details the aluminum extrusion process, highlights the strengths of the French industry, and provides actionable insights for businesses seeking reliable OEM partners. Whether you are an industry professional, a procurement specialist, or an entrepreneur looking to source aluminum extrusions, this article will help you understand the landscape and make informed decisions.

Understanding Aluminum Extrusion

Aluminum extrusion is a process that transforms solid aluminum billets into complex, continuous profiles by forcing the metal through a shaped die under high pressure. This method allows for the creation of intricate cross-sectional shapes tailored to specific applications, making it indispensable for industries such as construction, transportation, aerospace, automotive, and electronics.

The versatility of aluminum extrusion lies in its ability to produce lightweight, strong, and corrosion-resistant components. These properties make extruded aluminum profiles ideal for use in window frames, curtain walls, heat sinks, automotive chassis, and countless other products.

The Aluminum Extrusion Process: Step by Step

To appreciate the expertise of French aluminum extrusion press manufacturers and suppliers, it is essential to understand the process itself. Here's a step-by-step breakdown:

1. Billet Preparation

Aluminum billets, typically made from high-purity aluminum or specific alloys, are cut to the required size and preheated to around 450–500°C. This preheating softens the metal, making it malleable and easier to extrude.

2. Loading and Lubrication

The preheated billet is loaded into the extrusion press container. Lubricants are applied to both the billet and the die to minimize friction and prevent the aluminum from sticking to the surfaces during extrusion.

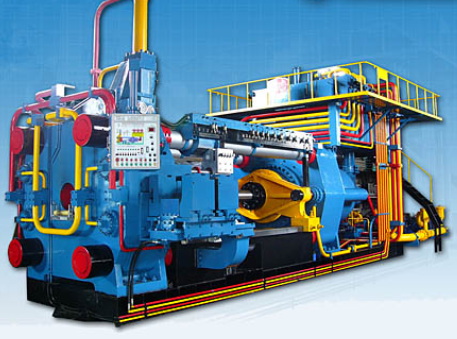

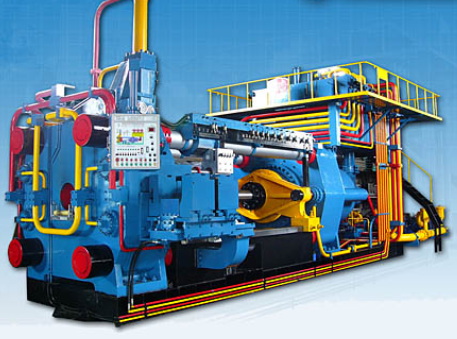

3. Extrusion

A powerful hydraulic ram applies immense pressure, pushing the billet through a precision-engineered die. The aluminum flows through the die opening, taking on the shape of the die's cross-section. This step is where the magic happens, as complex and custom profiles are formed in a continuous manner.

4. Quenching

As the extruded profile emerges from the die, it is rapidly cooled using water or air. This quenching process sets the metal's mechanical properties and helps prevent warping or distortion.

5. Cutting and Stretching

The extruded aluminum is cut to manageable lengths. It is then stretched to straighten and relieve internal stresses, ensuring dimensional accuracy and structural integrity.

6. Aging and Finishing

Depending on the alloy and application, the extruded profiles may undergo artificial aging (heat treatment) to achieve the desired strength. Additional finishing processes such as anodizing, powder coating, machining, drilling, or assembly may also be performed to meet customer specifications.

Key Aluminum Extrusion Press Manufacturers and Suppliers in France

France's aluminum extrusion industry features a mix of multinational corporations, specialized OEM suppliers, and innovative mid-sized companies. Below are the most prominent players in the market:

Exlabesa Flandria

Exlabesa Flandria is a leader in the French and Northern European aluminum extrusion market. With over five decades of experience, the company operates a state-of-the-art facility near Lille, equipped with two powerful extrusion presses (3500 Tn and 2400 Tn). Exlabesa Flandria's production capacity exceeds 18,000 tons per year, and the company is renowned for its commitment to sustainability, recycling, and low-carbon aluminum production.

Exlabesa Flandria serves a diverse customer base, including construction, transportation, and industrial sectors, and offers comprehensive services such as CNC machining, surface treatment, bending, and recycling. Their ability to deliver both standard and custom profiles makes them a preferred partner for OEMs and international brands.

Aluminium France Extrusion

With major production sites in Ham and Saint-Florentin, Aluminium France Extrusion is a key supplier of high-quality aluminum profiles for the French and European markets. The company excels in custom profile design and extrusion, supporting industries such as automotive, construction, and manufacturing. Their focus on innovation, technical support, and flexibility has earned them a strong reputation among OEMs and wholesalers.

Aluminium France Extrusion's R&D department collaborates closely with clients to develop new solutions, optimize designs, and ensure the highest standards of quality and performance.

Constellium

Constellium is a global leader in advanced aluminum solutions, with several facilities in France dedicated to extrusion, tube, and bar products. The company's expertise spans automotive, transport, energy, and construction markets, providing both standard and highly customized extrusions. Constellium's commitment to R&D and sustainability has positioned it as a trusted supplier for demanding applications, from lightweight automotive components to high-performance industrial systems.

Profils Systèmes

Profils Systèmes stands out for its integrated and eco-friendly approach to aluminum extrusion. Based in Baillargues, the company's 48,000 m² facility houses the entire production process, from R&D to finishing and logistics. Profils Systèmes is recognized for its “Made in France” label, high-performance products, and sustainable manufacturing practices. Their 2200-ton extrusion press, vertical lacquering, and thermal strutting capabilities enable them to serve architectural, industrial, and OEM clients with precision and reliability.

Hydro Aluminium Extrusion Services S.A.

Hydro, a global aluminum company, maintains a significant presence in France. Its Lucé plant recently underwent a €6 million upgrade, enhancing equipment, infrastructure, and employee training. Hydro's French operations focus on delivering high-quality extrusions for industrial and architectural applications, supported by the company's global expertise in sustainability and innovation.

Sapa Extrusion France

Now part of Hydro, Sapa Extrusion France continues to be a major supplier of aluminum extrusions, offering customized solutions for a variety of industries. Sapa's technical know-how, advanced extrusion technologies, and value-added services make it a go-to partner for OEMs and manufacturers seeking tailored aluminum profiles.

Other Notable Suppliers

The French market also features several other reputable aluminum extrusion press manufacturers and suppliers, including:

- Technal: Known for architectural systems and building solutions.

- Flandria Aluminium: Specializes in custom and standard profiles.

- Peraluman: Offers a wide range of extrusion services for industrial applications.

- Reynaers Aluminium: Focuses on innovative building and construction solutions.

- Kloeckner Metals France: Provides comprehensive metal supply services, including aluminum extrusions.

- DAL'ALU: Specializes in rainwater systems and building products.

These companies contribute to the diversity and strength of the French aluminum extrusion ecosystem, ensuring that buyers have access to a wide range of products and services.

OEM and Custom Manufacturing Capabilities

One of the defining strengths of French aluminum extrusion press manufacturers and suppliers is their ability to provide OEM and custom manufacturing services. This includes:

- Custom Die Design: French manufacturers work closely with clients to design and produce bespoke extrusion dies, enabling the creation of unique profiles for specialized applications.

- Flexible Production: Whether you need small prototype runs or large-scale production, French suppliers can accommodate varying order sizes with consistent quality.

- Value-Added Services: Beyond extrusion, many companies offer machining, drilling, cutting, anodizing, powder coating, thermal strutting, and assembly. This integrated approach streamlines the supply chain and reduces lead times.

- Quality Assurance: French manufacturers adhere to rigorous quality control standards, often certified by international bodies such as ISO and Qualicoat.

- International Compliance: Products are designed and manufactured to meet European and global standards, ensuring compatibility with international markets.

OEM customers benefit from the technical expertise, collaborative approach, and commitment to innovation that characterize the French aluminum extrusion industry.

Industry Trends and Innovations

The aluminum extrusion sector in France is constantly evolving, driven by technological advancements, sustainability goals, and changing market demands. Some of the key trends include:

1. Sustainability and Low-Carbon Aluminum

French manufacturers are investing heavily in recycling and low-carbon aluminum production. By incorporating recycled materials and optimizing energy efficiency, they reduce the environmental impact of extrusion processes. This aligns with global sustainability goals and enhances the appeal of French aluminum products in eco-conscious markets.

2. Digitalization and Automation

The adoption of Industry 4.0 technologies is transforming aluminum extrusion facilities across France. Automation, robotics, and digital monitoring systems improve process control, boost productivity, and ensure consistent quality. These innovations enable manufacturers to respond quickly to customer needs and maintain a competitive edge.

3. Advanced Alloys and Lightweighting

Research and development efforts are focused on creating new aluminum alloys with enhanced strength, corrosion resistance, and formability. This supports the trend toward lightweighting in automotive, aerospace, and transportation sectors, where reducing weight translates to improved fuel efficiency and lower emissions.

4. Customization and Design Flexibility

Modern extrusion presses and die technologies allow for greater design freedom and customization. French suppliers are increasingly offering tailored solutions, working closely with OEMs to develop profiles that meet specific functional and aesthetic requirements.

5. Globalization and Export Growth

French aluminum extrusion press manufacturers and suppliers are expanding their reach in international markets. Their reputation for quality, innovation, and reliability makes them attractive partners for global OEMs, wholesalers, and distributors.

Why Choose French Aluminum Extrusion Press Manufacturers and Suppliers?

Selecting a French aluminum extrusion press manufacturer or supplier offers several compelling advantages:

- Quality and Reliability: French companies are known for their meticulous attention to detail, robust quality control systems, and adherence to international standards.

- Innovation: Continuous investment in R&D ensures that French manufacturers remain at the forefront of technological advancements in aluminum extrusion.

- Sustainability: Commitment to recycling, energy efficiency, and low-carbon production supports environmentally responsible sourcing.

- Customization: The ability to deliver bespoke solutions for a wide range of industries and applications.

- Strategic Location: France's central position in Europe facilitates efficient logistics, quick delivery times, and access to major markets.

Whether you are seeking standard extrusion profiles or highly specialized OEM components, French suppliers offer a unique combination of technical expertise, manufacturing capability, and customer-focused service.

Conclusion

France stands out as a hub for aluminum extrusion press manufacturing and supply, offering a blend of tradition, innovation, and sustainability. From industry giants like Constellium and Hydro to specialized OEM partners such as Exlabesa Flandria and Profils Systèmes, French companies deliver high-quality, customized solutions for clients worldwide. Their expertise in the aluminum extrusion process, commitment to R&D, and focus on sustainability make them ideal partners for businesses seeking reliable and innovative aluminum products.

By understanding the strengths of French aluminum extrusion press manufacturers and suppliers, businesses can make informed sourcing decisions, benefit from advanced manufacturing capabilities, and contribute to a more sustainable future.

Frequently Asked Questions (FAQ)

Q1: What is the aluminum extrusion process, and why is it important?

A1: Aluminum extrusion is a process where heated aluminum billets are forced through a die to create continuous profiles with specific cross-sections. This process is vital for producing lightweight, strong, and corrosion-resistant components used in various industries.

Q2: Which industries benefit most from aluminum extrusions?

A2: Key industries include construction, automotive, aerospace, transportation, electronics, and renewable energy. Aluminum extrusions are valued for their versatility, strength, and design flexibility.

Q3: Can French manufacturers provide OEM and custom extrusion services?

A3: Yes, leading French aluminum extrusion press manufacturers and suppliers offer comprehensive OEM and custom manufacturing services, including die design, production, finishing, and assembly.

Q4: How do French suppliers ensure product quality and sustainability?

A4: French manufacturers implement rigorous quality control, invest in advanced technology, and often operate recycling centers to produce low-carbon aluminum profiles, ensuring both quality and environmental responsibility.

Q5: What are the main advantages of sourcing aluminum extrusions from France?

A5: Advantages include high product quality, innovative solutions, environmental responsibility, customization options, and strategic access to European and global markets.