Content Menu

● 1. Overview of the South Korean Aluminum Extrusion Industry

● 2. Leading Aluminum Extrusion Line Manufacturers and Suppliers

>> SKM Korea

>> HAI & LS Cable

>> Sunwoo Engineering Co., Ltd.

>> ALUS Co., Ltd.

>> Daeyeong Metal

>> Jinwoo Metal

● 3. Technological Innovations in Aluminum Extrusion

● 4. South Korea's Role in the Global Supply Chain

● 5. Insights into the Import and Export Market

● 6. Challenges and Opportunities in the Korean Aluminum Extrusion Industry

● 7. Future Trends in Aluminum Extrusion Technology

● Conclusion

● Frequently Asked Questions

>> Q1: What are the main applications of aluminum extrusions produced in South Korea?

>> Q2: Can South Korean manufacturers provide OEM and customized extrusion solutions?

>> Q3: What technological advantages do South Korean extrusion lines offer?

>> Q4: How do Korean suppliers ensure product quality and compliance?

>> Q5: What is the export potential for aluminum extrusion lines from South Korea?

South Korea stands as a global leader in advanced manufacturing, and its aluminum extrusion industry is no exception. The nation is home to some of the world's most innovative aluminum extrusion line manufacturers and suppliers, serving a wide range of sectors including automotive, construction, electronics, and renewable energy. This article provides a comprehensive overview of the top players in South Korea's aluminum extrusion market, their technological advancements, and the unique value they bring to the global supply chain.

1. Overview of the South Korean Aluminum Extrusion Industry

South Korea's aluminum extrusion sector is characterized by high-quality manufacturing, technological innovation, and robust export capabilities. The industry supports a diverse range of applications, from lightweight automotive components to precision electronics housings and architectural structures. Korean manufacturers are renowned for their ability to deliver customized OEM solutions to international clients, making them highly sought after by global brands, wholesalers, and producers.

The country's focus on research and development, combined with its strategic location in Northeast Asia, has enabled South Korea to become a key supplier of aluminum extrusion lines and products to markets across the globe. The government's support for advanced manufacturing and export-driven growth has further strengthened the industry's competitiveness.

2. Leading Aluminum Extrusion Line Manufacturers and Suppliers

SKM Korea

SKM Korea is a pioneer in the development and design of extrusion technology for aluminum profiles. Since its founding in 1990, SKM has specialized in delivering complete extrusion processing manufacturing facilities, both domestically and internationally. Their product portfolio includes:

- Aluminum extrusion presses (front loading type, a first in Korea)

- Handling equipment

- Furnaces, melting, casting, and quenching facilities

- Anodizing plants

- Copper and brass extrusion presses

- Die casting technology

SKM's extrusion equipment ranges up to 8,500 tons, supporting both large-scale and specialized production needs. Their commitment to R&D ensures continuous innovation for high-precision and high-quality aluminum profiles. SKM's ability to offer turnkey solutions, from design to installation and after-sales service, makes them a preferred partner for companies seeking reliable and advanced aluminum extrusion lines.

HAI & LS Cable

In 2025, Hammerer Aluminium Industries (HAI), in partnership with LS Cable & System, launched a new, fully automated aluminum extrusion plant in Gumi, Gyeongsangbuk-do province. This $50 million investment features:

- A 13,800 m² production hall

- A fully automated extrusion line with a pressing force of 60 meganewtons

- Comprehensive upstream and downstream systems for advanced manufacturing

The facility is designed to produce complex aluminum components for the South Korean market, particularly for electromobility and high-tech industries. The rapid ramp-up and high quality of the plant underscore South Korea's capacity for large-scale, technologically advanced aluminum extrusion solutions. HAI & LS Cable's collaboration also exemplifies the growing trend of joint ventures and strategic partnerships in the Korean aluminum extrusion industry, aimed at leveraging complementary strengths and expanding market reach.

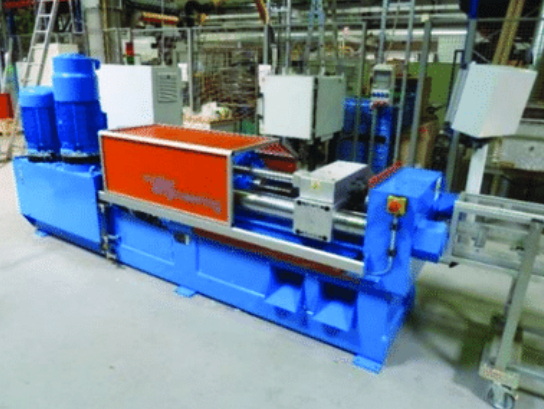

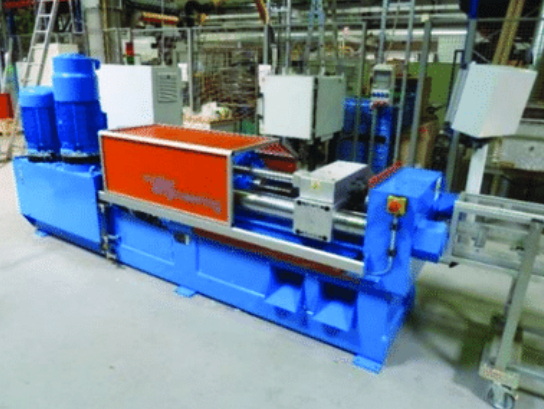

Sunwoo Engineering Co., Ltd.

Sunwoo Engineering is a leading Korean manufacturer specializing in:

- Aluminum extrusion press lines for general profiles

- Multiport extruded (MPE) tube production lines for automotive and HVAC industries

- Precision tubing lines

Established in 1989, Sunwoo has supplied over 180 extrusion presses and ancillary equipment to both the domestic and international markets, including the US and Japan. Their machines are known for their robust structure, minimal maintenance needs, and short dead cycle times. Sunwoo's focus on strict tolerances and competitive pricing makes them a preferred partner for OEM projects worldwide. The company's dedication to customer satisfaction is evident in its comprehensive after-sales support and continuous product improvement.

ALUS Co., Ltd.

Founded in 1999, ALUS Co., Ltd. has built a reputation for delivering high-quality aluminum extrusion products. Their strengths include:

- Advanced alloy design and casting capabilities

- Mold design and extrusion expertise

- Serving both domestic and international clients

ALUS's focus on quality and innovation has made them a trusted supplier for demanding applications in various industries. The company's investment in state-of-the-art equipment and skilled personnel ensures that it can meet the evolving needs of its clients, from prototyping to mass production.

Daeyeong Metal

Daeyeong Metal specializes in manufacturing a wide range of aluminum extrusion products, including:

- Aluminum tubes and chassis

- Cylinders and profiles

Their products are widely used in the automotive, industrial, and construction sectors, and they are recognized for their precision and reliability. Daeyeong Metal's commitment to quality control and continuous improvement has enabled it to maintain long-term relationships with both domestic and international customers.

Jinwoo Metal

Jinwoo Metal is another significant player in the Korean aluminum extrusion landscape. Their factory, located in Gimpo, Gyeonggi-do, is featured in manufacturing documentaries that showcase the entire aluminum pipe mass production process—from billet loading and high-temperature extrusion to high-pressure pipe cutting and heat treatment.

Jinwoo Metal's expertise in producing high-quality aluminum pipes and profiles has positioned it as a reliable supplier for a variety of industries, including automotive, construction, and industrial equipment manufacturing.

3. Technological Innovations in Aluminum Extrusion

South Korean aluminum extrusion line manufacturers and suppliers are at the forefront of technological advancement. Key innovations include:

- Automated extrusion lines: Facilities like HAI & LS Cable's Gumi plant feature fully automated systems for efficiency and quality control.

- Front loading extrusion presses: Developed by SKM, these presses increase productivity and enable the production of high-precision profiles.

- Advanced alloy and mold design: Companies like ALUS focus on custom alloy development and precision mold design for tailored solutions.

- Integration of upstream and downstream processes: Comprehensive systems for melting, casting, quenching, and anodizing ensure a seamless production flow and consistent product quality.

South Korean manufacturers also invest heavily in digitalization and smart manufacturing technologies. The use of IoT sensors, real-time data analytics, and predictive maintenance tools helps optimize production efficiency, reduce downtime, and improve product traceability. These innovations not only enhance the competitiveness of Korean aluminum extrusion line manufacturers and suppliers but also support sustainability by minimizing energy consumption and material waste.

4. South Korea's Role in the Global Supply Chain

South Korea's aluminum extrusion industry is deeply integrated into the global supply chain. The country not only exports finished aluminum profiles and components but also supplies complete extrusion lines and OEM solutions to international partners. Korean manufacturers are known for their:

- OEM and ODM capabilities: Serving international brands, wholesalers, and manufacturers with customized solutions.

- Export orientation: Major markets include the United States, Japan, China, India, and Southeast Asia.

- Compliance with global standards: Korean products meet stringent quality and environmental standards, making them attractive to global buyers.

The strategic geographic location of South Korea, combined with its advanced logistics infrastructure, enables efficient distribution of aluminum extrusion products and equipment to customers worldwide. This global reach is further supported by participation in international trade fairs, industry associations, and collaborative R&D projects.

5. Insights into the Import and Export Market

According to recent trade data, South Korea imports and exports significant volumes of aluminum extrusions. Noteworthy trends include:

- Diverse buyer base: There are 64 active aluminum extrusions importers in South Korea, sourcing from 131 global suppliers.

- Major importers: Companies like SEOJIN SYSTEM VINA CO LTD, INTELLIAN TECHNOLOGIES INC, and SEOJIN SYSTEM CO LTD account for the majority of imports.

- Export destinations: Korean manufacturers export to over 133 countries, with detailed shipment data available for market analysis and strategic targeting.

The export of aluminum extrusion lines and products is supported by comprehensive documentation, quality certifications, and after-sales service, which are essential for building trust with international customers. Korean suppliers are also adept at navigating complex international regulations and standards, ensuring smooth cross-border transactions.

6. Challenges and Opportunities in the Korean Aluminum Extrusion Industry

While South Korea's aluminum extrusion industry enjoys many strengths, it also faces several challenges:

- Raw material costs: Fluctuations in the global price of aluminum can impact profitability.

- Competition from China and other low-cost producers: Korean manufacturers must continuously innovate and focus on quality to differentiate themselves.

- Environmental regulations: Increasingly stringent environmental standards require ongoing investment in cleaner production technologies and recycling initiatives.

However, these challenges also present opportunities. The global shift toward lightweight materials in automotive and aerospace sectors is driving demand for high-performance aluminum extrusions. The rise of renewable energy projects, such as solar panel frames and wind turbine components, offers new growth avenues. South Korean manufacturers are well-positioned to capitalize on these trends by leveraging their technological expertise and commitment to sustainability.

7. Future Trends in Aluminum Extrusion Technology

Looking ahead, several trends are expected to shape the future of the aluminum extrusion industry in South Korea:

- Increased automation and digitalization: The adoption of Industry 4.0 technologies will further enhance productivity, quality, and flexibility.

- Development of advanced alloys: Research into new aluminum alloys with improved strength, corrosion resistance, and formability will enable the creation of lighter and more durable products.

- Sustainability initiatives: Greater emphasis on recycling, energy efficiency, and eco-friendly production processes will align with global environmental goals.

- Customization and rapid prototyping: The ability to quickly develop and produce customized aluminum profiles will become a key competitive advantage.

South Korean aluminum extrusion line manufacturers and suppliers are investing in these areas to maintain their leadership in the global market and meet the evolving needs of their customers.

Conclusion

South Korea is home to some of the world's top aluminum extrusion line manufacturers and suppliers, including SKM Korea, HAI & LS Cable, Sunwoo Engineering, ALUS, Daeyeong Metal, and Jinwoo Metal. These companies drive innovation through advanced automation, robust OEM capabilities, and a commitment to quality, making South Korea a global hub for aluminum extrusion technology and supply. With a strong focus on technological advancement, sustainability, and customer satisfaction, South Korean manufacturers are well-positioned to meet the growing demands of the international market and continue their leadership in the aluminum extrusion industry.

Frequently Asked Questions

Q1: What are the main applications of aluminum extrusions produced in South Korea?

A: South Korean aluminum extrusions are widely used in automotive, electronics, construction, renewable energy, and industrial machinery due to their lightweight, strength, and corrosion resistance.

Q2: Can South Korean manufacturers provide OEM and customized extrusion solutions?

A: Yes, most leading manufacturers offer comprehensive OEM and ODM services, including custom alloy design, mold development, and tailored production to meet specific client requirements.

Q3: What technological advantages do South Korean extrusion lines offer?

A: Key advantages include automated production lines, front loading extrusion presses, advanced quality control, and integration of upstream/downstream processes for higher efficiency and precision.

Q4: How do Korean suppliers ensure product quality and compliance?

A: Manufacturers adhere to strict quality management systems, utilize advanced testing equipment, and comply with international standards such as ISO and environmental certifications.

Q5: What is the export potential for aluminum extrusion lines from South Korea?

A: South Korea is a major exporter of both finished aluminum extrusions and complete extrusion lines, with a strong presence in North America, Europe, and Asia-Pacific markets.