Content Menu

● Introduction to HDPE Single Wall Corrugated Pipes

>> Features of HDPE Single Wall Corrugated Pipes

● Components of the HDPE Single Wall Corrugated Pipe Extrusion Line

● Production Process of HDPE Single Wall Corrugated Pipes

>> Material Loading

>> Melting and Mixing

>> Pipe Formation

>> Corrugation

>> Cooling

>> Haul-Off and Cutting

● Applications of HDPE Single Wall Corrugated Pipes

● Advantages of Using HDPE Single Wall Corrugated Pipe Extrusion Lines

● Challenges and Future Developments

● Conclusion

● FAQs

>> 1. What are the primary components of an HDPE single wall corrugated pipe extrusion line?

>> 2. How does the corrugation process enhance the pipe's properties?

>> 3. What are the common applications of HDPE single wall corrugated pipes?

>> 4. What are the advantages of using HDPE single wall corrugated pipes?

>> 5. How does the cooling system affect the final product?

● Citations:

HDPE single wall corrugated pipes are widely used in various applications, including drainage systems, electrical wiring protection, and other industrial uses. These pipes are valued for their flexibility, corrosion resistance, and cost-effectiveness. The production of these pipes involves a sophisticated process utilizing specialized machinery known as the plastic machinery HDPE single wall corrugated pipe extrusion line. This article will delve into the details of how this machinery works, highlighting each stage of the production process.

Introduction to HDPE Single Wall Corrugated Pipes

HDPE single wall corrugated pipes are made from high-density polyethylene (HDPE), a thermoplastic material known for its durability and resistance to environmental stressors. The corrugation process enhances the pipe's flexibility and structural integrity, making it suitable for applications where bending and impact resistance are crucial.

Features of HDPE Single Wall Corrugated Pipes

- Flexibility: Allows for easy installation and resistance to bending.

- Corrosion Resistance: Suitable for use in environments with high chemical exposure.

- Cost-Effectiveness: Lower material and installation costs compared to other piping materials.

- Lightweight: Facilitates transportation and handling.

Components of the HDPE Single Wall Corrugated Pipe Extrusion Line

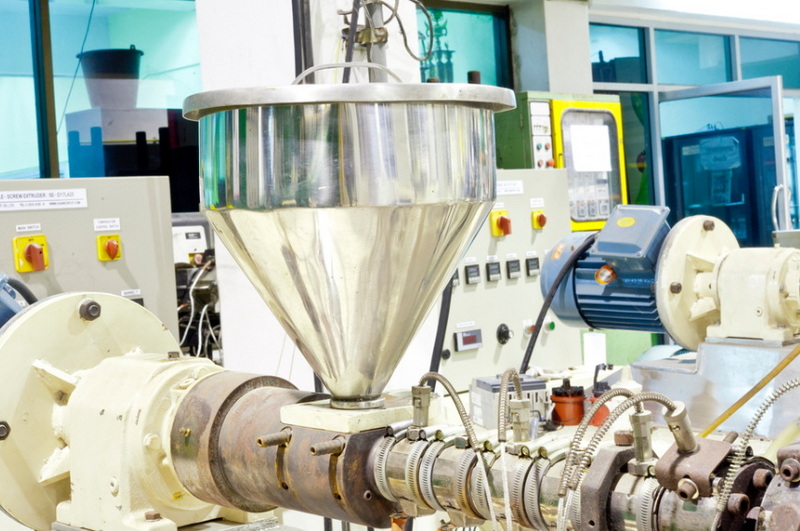

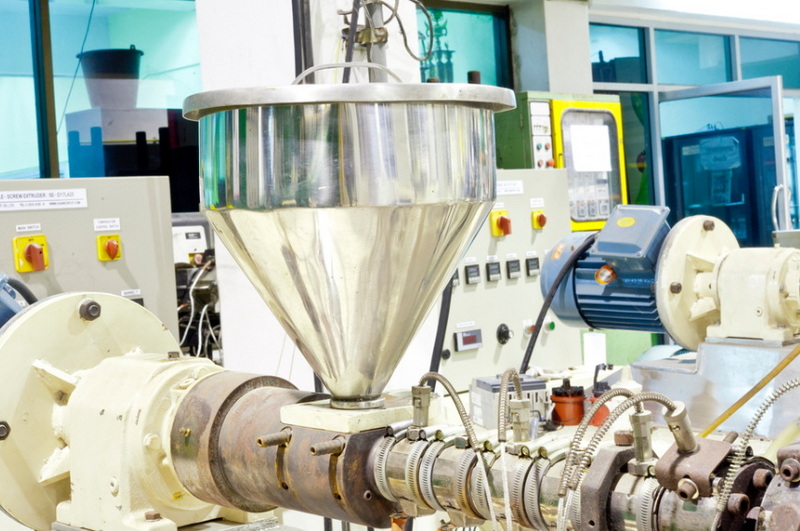

The plastic machinery HDPE single wall corrugated pipe extrusion line consists of several key components, each playing a critical role in the production process:

1. Extruder: This is the core component responsible for melting and mixing the HDPE resin. It consists of a heated barrel and a screw that ensures uniform melting and mixing of the material. The extruder's design and capacity can significantly affect the production rate and quality of the pipes.

2. Die: The molten HDPE is pushed through a die, which shapes it into a cylindrical tube. The die's design determines the pipe's diameter and wall thickness. Precise control over the die's temperature and pressure is essential for achieving consistent pipe dimensions.

3. Corrugation Forming Machine: This machine reshapes the tube into a corrugated profile using molds and vacuum or forced air technology. The corrugation process not only enhances the pipe's flexibility but also increases its surface area, which can improve its structural integrity.

4. Cooling System: The corrugated pipe is cooled using air or water to solidify and maintain its shape. The cooling process is critical as it affects the final product's quality and performance. Proper cooling ensures that the pipe retains its corrugated shape and achieves the desired mechanical properties.

5. Haul-Off Unit: This unit pulls the cooled pipe through the production line, ensuring continuous production. The haul-off unit must be synchronized with the extruder and corrugation machine to maintain a consistent production speed.

6. Cutting Unit: Cuts the pipe into desired lengths. The cutting unit is typically equipped with a precision cutting tool to ensure clean cuts and minimize waste.

Production Process of HDPE Single Wall Corrugated Pipes

The production process involves several stages:

Material Loading

HDPE resin pellets are loaded into the extruder's hopper. The pellets are gravity-fed into the extruder barrel, where they are melted and mixed with any additives.

Melting and Mixing

The HDPE pellets are melted and mixed in the extruder. The screw ensures uniform heating and mixing, which is crucial for achieving consistent material properties throughout the pipe.

Pipe Formation

The molten HDPE is pushed through the die, forming a cylindrical tube. The die's design and temperature control are critical at this stage to ensure the tube has the correct dimensions and wall thickness.

Corrugation

The tube is reshaped into a corrugated profile using a corrugation forming machine. This process involves applying pressure and vacuum to create the corrugations, which enhance the pipe's flexibility and structural integrity.

Cooling

The corrugated pipe is cooled to solidify and maintain its shape. The cooling method—whether air or water—is chosen based on the production speed and desired pipe properties.

Haul-Off and Cutting

The cooled pipe is pulled through the haul-off unit and cut into desired lengths. The cutting process is typically automated to ensure precision and efficiency.

Applications of HDPE Single Wall Corrugated Pipes

These pipes are used in various applications due to their flexibility and cost-effectiveness:

- Drainage Systems: Ideal for residential and commercial drainage projects. Their flexibility allows them to be easily installed in complex layouts.

- Electrical Wiring Protection: Used to protect electrical cables in construction and automotive industries. The corrugated design provides additional protection against mechanical damage.

- Industrial Uses: Suitable for applications requiring flexibility and resistance to environmental stressors, such as chemical plants and agricultural systems.

Advantages of Using HDPE Single Wall Corrugated Pipe Extrusion Lines

- Efficiency: Continuous production process ensures high output rates, making it suitable for large-scale projects.

- Flexibility: Pipes can be easily bent without cracking, which simplifies installation in tight spaces.

- Cost-Effective: Lower production and installation costs compared to other materials, such as metal or PVC pipes.

- Environmental Resistance: HDPE pipes are resistant to corrosion and chemical degradation, extending their lifespan in harsh environments.

Challenges and Future Developments

Despite the advantages of HDPE single wall corrugated pipes, there are challenges related to recycling and environmental impact. Future developments focus on improving recyclability and reducing waste in the production process. Additionally, advancements in machinery technology aim to increase production efficiency and reduce energy consumption.

Conclusion

The plastic machinery HDPE single wall corrugated pipe extrusion line plays a crucial role in producing pipes that are essential for modern infrastructure and industrial applications. Understanding the components and process of this machinery is vital for optimizing production efficiency and ensuring the quality of the final product.

FAQs

1. What are the primary components of an HDPE single wall corrugated pipe extrusion line?

The primary components include the extruder, die, corrugation forming machine, cooling system, haul-off unit, and cutting unit.

2. How does the corrugation process enhance the pipe's properties?

The corrugation process increases the pipe's flexibility and structural integrity, making it more resistant to bending and impact.

3. What are the common applications of HDPE single wall corrugated pipes?

These pipes are commonly used in drainage systems, electrical wiring protection, and various industrial applications.

4. What are the advantages of using HDPE single wall corrugated pipes?

Advantages include flexibility, cost-effectiveness, corrosion resistance, and ease of installation.

5. How does the cooling system affect the final product?

The cooling system ensures that the corrugated pipe solidifies and maintains its shape, which is crucial for its structural integrity and performance.

Citations:

[1] https://sinopipefactory.com/blog/understanding-the-hdpe-pipe-extrusion-process-a-comprehensive-guide/

[2] https://fa.parsethylene-kish.com/UserFiles/Uploads/chapter%203.pdf

[3] https://www.qiangshengplas.com/pp-pe-pvc-single-wall-corrugated-pipe-extrusion-line-product/

[4] https://www.youtube.com/watch?v=tehWzXwXtjg

[5] https://www.youtube.com/watch?v=Kv9wpOf5iVg

[6] https://machine.goldsupplier.com/blog/hdpe-pipe-extrusion-process/

[7] https://www.adspipe.com/pipe/single-wall-pipe

[8] https://www.benkpm.com/corrugated-pipe-extrusion-line/

[9] https://blog.epcland.com/hdpe-pipes/

[10] https://qdsuke.en.made-in-china.com/product/yKmJNjlcLXYq/China-PE-HDPE-Single-Wall-Corrugated-Pipe-Extrusion-Making-Machine.html

[11] https://kaidemac.en.made-in-china.com/product/GxFRpNJURAhr/China-HDPE-Single-Wall-Corrugated-Pipe-Machine-PE-PP-Single-Wall-Corrugated-Pipe-Production-Extrusion-Line.html

[12] https://tongsanmachine.en.made-in-china.com/product/XFetUhWvnYrI/China-PE-HDPE-Single-Wall-Corrugated-Pipe-Machine-Plastic-Corrugated-Tube-Culvert-Extruder.html

[13] https://www.alibaba.com/product-detail/Plastics-Single-Wall-Hdpe-Corrugated-Drainage_1601029802547.html

[14] https://www.alibaba.com/product-detail/New-Single-Wall-Corrugated-Pipe-System_1601175005560.html

[15] https://qdcuishi.en.made-in-china.com/product/EndYFktrVGRI/China-Corrugated-Pipe-Extrusion-Line-HDPE-Pipe-Extruder-Machine.html

[16] https://www.tophdextruder.com/corrugated-pipe-production-line/

[17] https://www.jtpipeline.com/product/hdpe-single-wall-corrugated-pipe

[18] https://wingsplastic.en.made-in-china.com/product/YBJmkZsyLcpO/China-Plastic-HDPE-PVC-Single-Wall-Corrugated-Pipe-Extrusion-Production-Line.html

[19] https://www.youtube.com/watch?v=cbqHk3C-Tpk

[20] https://boya-tech.goldsupplier.com/product.html?groupid=259113

[21] https://www.alibaba.com/product-detail/single-wall-corrugated-pipe-production-line_1600238111840.html