Content Menu

● Understanding Aluminum Extrusion

>> Advantages of Aluminum Extrusion Fittings

● Applications of Aluminum Extrusion Fittings

● Getting Started with Your DIY Project

● Tips for Using Aluminum Extrusion Fittings Effectively

● Creative Project Ideas Using Aluminum Extrusion Fittings

● Visual Inspiration

● Conclusion

● FAQ

>> 1. What are aluminum extrusion fittings?

>> 2. Are aluminum extrusions easy to work with?

>> 3. Can I modify my design after assembly?

>> 4. What tools do I need for working with aluminum extrusions?

>> 5. How do I ensure stability in my aluminum structure?

● Citations:

Aluminum extrusion fittings have gained immense popularity among DIY enthusiasts and professionals alike. Their versatility, strength, and ease of use make them an ideal choice for a wide range of projects. In this article, we will explore the benefits of aluminum extrusion fittings, how they can enhance your DIY projects, and provide practical tips for using them effectively.

Understanding Aluminum Extrusion

Aluminum extrusion is a manufacturing process that transforms aluminum alloy into objects with a specific cross-sectional profile. This is achieved by forcing preheated aluminum billets through a shaped die, resulting in elongated shapes with uniform cross-sections. The process is highly efficient and allows for the creation of complex designs that are lightweight yet strong.

Advantages of Aluminum Extrusion Fittings

- Lightweight and Durable: Aluminum has a high strength-to-weight ratio, making it ideal for applications requiring both strength and reduced weight.

- Corrosion Resistance: The natural oxide layer that forms on aluminum surfaces protects against corrosion, making it suitable for outdoor and industrial applications.

- Modularity: Aluminum extrusion fittings are designed to be modular. This means you can easily assemble, disassemble, and reconfigure structures without specialized tools.

- Customization: With a variety of profiles available, aluminum extrusions can be tailored to meet specific project needs.

- Ease of Assembly: The T-slot design allows for quick assembly using basic tools. Components can be joined without welding, making it accessible for DIY projects.

Applications of Aluminum Extrusion Fittings

Aluminum extrusion fittings are used in various applications:

- Furniture Construction: Create custom furniture pieces like tables, shelves, and workstations. The modularity allows for easy adjustments and reconfigurations to suit different spaces or functions.

- Machine Frames: Build sturdy frames for 3D printers, CNC machines, or robotic systems. The lightweight nature of aluminum helps reduce the overall weight of the machinery while maintaining structural integrity.

- Display Stands: Design attractive display stands for retail or exhibitions. The sleek appearance of aluminum enhances the visual appeal of products on display.

- Safety Guards: Construct protective barriers or guards in industrial settings. These fittings can be used to create safety enclosures around machinery or hazardous areas.

- Automated Systems: Integrate motion systems and sensors into your designs easily. Aluminum extrusions can be used to create tracks or frameworks for automated processes.

Getting Started with Your DIY Project

1. Design Your Project: Start by sketching your design. Consider the dimensions and how the aluminum extrusions will fit together. Utilize design software if necessary to visualize your project better.

2. Select the Right Profiles: Choose the appropriate aluminum extrusion profiles based on your project's requirements. Common sizes include 20mm x 20mm or 40mm x 40mm profiles, but many other dimensions are available depending on your needs.

3. Gather Accessories: Collect necessary accessories such as connectors, brackets, and fasteners. These components will facilitate assembly and ensure structural integrity. Consider purchasing a starter kit that includes various fittings to get started quickly.

4. Prepare Tools: Basic tools needed include an Allen wrench, a saw (for cutting extrusions), and a drill (for creating holes if necessary). Ensure you have a clean workspace with adequate lighting to avoid accidents during assembly.

5. Assemble Your Structure: Follow your design to assemble the structure using the T-slot system. Ensure all connections are secure but not overly tight to allow for adjustments if needed. Use a level to check that everything is aligned properly during assembly.

Tips for Using Aluminum Extrusion Fittings Effectively

- Plan for Adjustability: When designing your project, consider future modifications. Use adjustable brackets to allow changes without complete disassembly. This foresight can save time and effort in future upgrades or repairs.

- Test Stability: After assembly, test the stability of your structure before full use. Make adjustments as necessary to ensure safety and durability. If building larger structures, consider adding diagonal braces for additional support.

- Utilize Accessories Wisely: Take advantage of various accessories like gussets and brackets to reinforce joints where necessary. These additions can significantly enhance the overall strength of your project.

- Maintain Cleanliness: Keep your workspace clean to avoid losing small components during assembly. Establish a designated area for tools and materials to streamline your workflow.

Creative Project Ideas Using Aluminum Extrusion Fittings

To inspire your next DIY project, here are some creative ideas that utilize aluminum extrusion fittings:

- Custom Workbench: Build a sturdy workbench tailored to your specific needs using aluminum extrusions as the frame. Add shelves underneath for storage and incorporate a pegboard on the back for tool organization.

- Modular Shelving System: Create a modular shelving system that can be adjusted based on changing storage needs. Use different lengths of extrusions to create varying shelf heights and widths.

- Portable Display Booth: Design a portable display booth for trade shows or craft fairs using lightweight aluminum extrusions that can be easily assembled and disassembled for transport.

- Aquarium Stand: Construct an aquarium stand that provides both stability and aesthetic appeal with aluminum extrusions. Incorporate storage space below for supplies like food and cleaning equipment.

Visual Inspiration

To aid in your understanding of aluminum extrusion fittings and their applications, here are some visual examples:

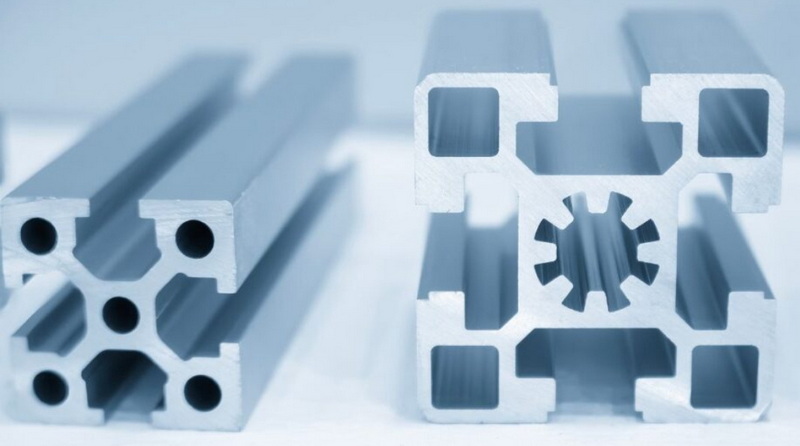

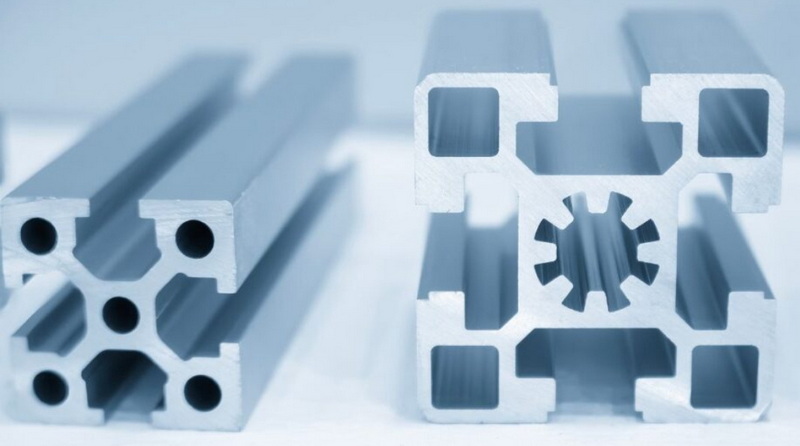

Aluminum Extrusion Profiles

Aluminum Extrusion Profiles

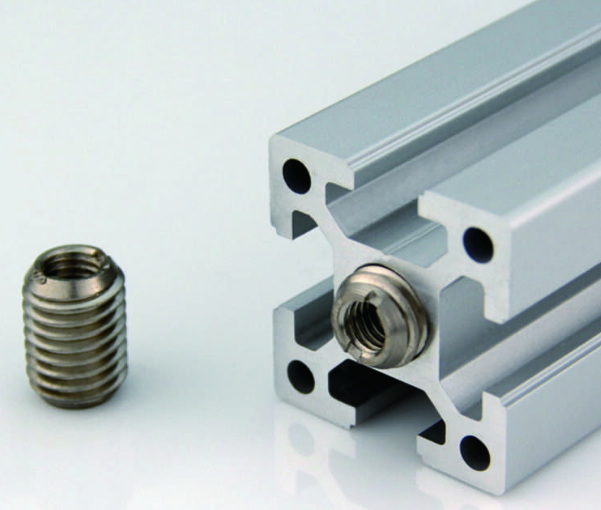

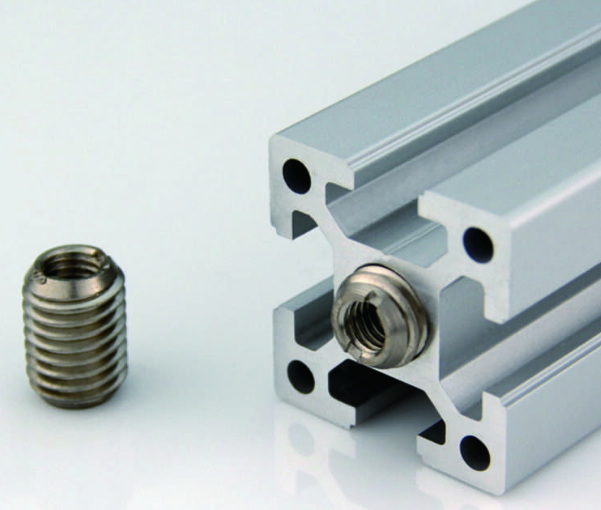

DIY Project Using Aluminum Extrusions

DIY Project Using Aluminum Extrusions

Assembly Process

Assembly Process

Conclusion

Aluminum extrusion fittings offer unparalleled versatility and ease of use for DIY projects. Their lightweight yet strong nature makes them ideal for various applications ranging from furniture construction to industrial machinery frames. By taking advantage of their modularity and customization options, you can create structures that are not only functional but also aesthetically pleasing.

With proper planning and execution, your next DIY project using aluminum extrusion fittings can be both enjoyable and successful. Embrace the creativity that comes with these materials and let your imagination guide you!

FAQ

1. What are aluminum extrusion fittings?

Aluminum extrusion fittings are components made from extruded aluminum profiles designed to connect or support other elements in construction projects.

2. Are aluminum extrusions easy to work with?

Yes! Aluminum extrusions are lightweight and designed for easy assembly without welding or specialized tools.

3. Can I modify my design after assembly?

Absolutely! The modular nature of aluminum extrusions allows you to easily disassemble and reconfigure your project as needed.

4. What tools do I need for working with aluminum extrusions?

Basic tools such as an Allen wrench, saw (for cutting), drill (for making holes), and standard fasteners are typically sufficient.

5. How do I ensure stability in my aluminum structure?

Test the stability after assembly by applying weight gradually and making adjustments as needed to reinforce joints with brackets or gussets if necessary.

Citations:

[1] https://jieyatwinscrew.com/blog/80-20-aluminum-extrusion/

[2] https://www.chaluminium.com/the-versatility-of-t-slot-aluminum-connection-advantages-methods-and-usage

[3] https://www.alamy.com/stock-photo/aluminum-extrusion.html

[4] https://www.youtube.com/watch?v=AqWG5TWy3qM

[5] https://www.industrialprofile.com/aluminum-extrusion-joints-design-and-assembly-considerations/

[6] https://www.gabrian.com/joining-aluminum-extrusions/

[7] https://blog.airlinehyd.com/how-to-build-anything-with-aluminum-extrusion-in-3-steps

[8] https://asaluminum.com/blog/exploring-the-art-of-aluminum-extrusion-methods-advantages-and-applications/

[9] https://www.youtube.com/watch?v=2mc9yjnnrSY

[10] https://technical.europe.misumi-ec.com/en/support/solutions/articles/76000046645-aluminum-extrusions-general-questions

[11] https://hackaday.com/2021/05/25/getting-started-with-aluminum-extrusions/

[12] https://us.misumi-ec.com/blog/diy-project-using-aluminum-extrusions/

[13] https://us.misumi-ec.com/maker/misumi/mech/product/al/faq/