Content Menu

● The South Korean Puller Industry Overview

>> Key Industry Highlights

● Leading Puller Manufacturers And Suppliers in South Korea

● Types of Pullers Produced in South Korea

>> Mechanical Pullers

>> Hydraulic Pullers

>> Gear Pullers

>> Cable and Wire Rope Pullers

>> Zipper Pullers

● Puller Manufacturing Process: From Design to Delivery

>> Design and Engineering

>> Material Selection

>> Precision Manufacturing

>> Assembly and Testing

>> Packaging and Delivery

● Why Choose South Korean Puller Manufacturers And Suppliers?

>> Superior Quality

>> Innovation and Technology

>> Customization and OEM Services

>> Competitive Pricing

>> Global Logistics

● OEM Services and Global Partnerships

● Puller Applications Across Industries

>> Automotive Industry

>> Construction and Heavy Equipment

>> Electrical and Utility Sectors

>> Textile and Apparel

>> Manufacturing and Maintenance

● Key Considerations When Selecting a Puller Supplier

>> Product Range and Specialization

>> Quality Assurance

>> Customization Capabilities

>> Communication and Support

>> Logistics and Delivery

● The Future of Puller Manufacturing in South Korea

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of pullers do South Korean manufacturers produce?

>> 2. Can South Korean puller manufacturers provide OEM services?

>> 3. How do South Korean puller manufacturers ensure product quality?

>> 4. What are the advantages of sourcing pullers from South Korea?

>> 5. How can I contact top puller manufacturers and suppliers in South Korea?

South Korea stands as a global leader in industrial manufacturing, with a robust ecosystem of puller manufacturers and suppliers. These companies provide a wide range of pullers, from mechanical and hydraulic pullers to specialized tools for automotive, construction, and heavy machinery industries. This article explores the top puller manufacturers and suppliers in South Korea, their product offerings, manufacturing processes, and the reasons why international buyers, including OEM clients, choose South Korean partners for their puller needs.

The South Korean Puller Industry Overview

South Korea's industrial sector is renowned for its innovation, quality, and efficiency. The country's puller manufacturers and suppliers have established a strong reputation for delivering high-performance products that meet international standards. With a focus on research and development, South Korean companies continuously improve their product lines to cater to the evolving needs of global industries.

Key Industry Highlights

- Over 900 registered puller manufacturers and suppliers operate in South Korea, serving both domestic and international markets.

- The industry covers a broad spectrum, including mechanical pullers, hydraulic pullers, gear pullers, cable pullers, and specialized tools for various sectors.

- South Korean puller manufacturers and suppliers are known for their commitment to quality, innovation, and customer service.

Leading Puller Manufacturers And Suppliers in South Korea

Below is a list of some of the most prominent puller manufacturers and suppliers in South Korea, recognized for their product quality, technological advancement, and global reach.

| Company Name | Specialization | Location | Notable Features |

| JK Technology | Heavy equipment attachments, pullers | Ansan-si, Gyeonggi-do | R&D focus, global distribution |

| Oh Sung Industries | Ratchet pullers, grips | South Korea | Durable, high-capacity tools |

| KOREA HYDMAG | Hydraulic pullers, high-pressure tools | South Korea | Advanced hydraulic solutions |

| Woojin Plastic | Plastic pullers, buckles | South Korea | Outdoor and industrial use |

| Magswitch Technology Korea | Magnetic pullers, industrial tools | South Korea | Innovative magnetic tech |

| Hansoll Textile Ltd | Zipper pullers | South Korea | Textile and apparel industry |

| Unico Global Inc | Zipper pullers | South Korea | OEM/ODM services |

| Youngone Outdoor Corporation | Zipper pullers | South Korea | Outdoor gear and apparel |

| Pungkook | Zipper pullers | South Korea | Large-scale production |

These companies represent the diversity and strength of South Korea's puller manufacturing sector, offering products for a wide range of applications.

Types of Pullers Produced in South Korea

South Korean puller manufacturers and suppliers produce a comprehensive range of pullers to meet the needs of various industries:

Mechanical Pullers

Mechanical pullers are widely used for removing gears, bearings, pulleys, and other press-fitted parts. They are available in two-jaw, three-jaw, and specialty configurations, ensuring versatility for different tasks. Mechanical pullers are essential in automotive repair, maintenance, and heavy equipment servicing.

Hydraulic Pullers

Hydraulic pullers are designed for heavy-duty applications requiring high force. They are commonly used in automotive, construction, and heavy machinery sectors where manual force is insufficient. Hydraulic pullers from South Korean suppliers are known for their safety features, efficiency, and ability to handle large-scale tasks.

Gear Pullers

Gear pullers are specialized tools for extracting gears from shafts. Precision engineering ensures that these tools can safely and efficiently remove gears without damaging the components. South Korean gear pullers are used in manufacturing plants, automotive workshops, and machinery maintenance.

Cable and Wire Rope Pullers

Cable and wire rope pullers provide mechanical advantage for pulling cables and wires, making them indispensable in construction, electrical, and utility industries. South Korean manufacturers offer robust and reliable cable pullers that meet stringent safety standards.

Zipper Pullers

Zipper pullers are essential components in the textile and apparel industry. South Korea is a major exporter of high-quality zipper pullers, supplying global brands with durable and stylish solutions for garments, bags, and outdoor gear.

Puller Manufacturing Process: From Design to Delivery

South Korean puller manufacturers and suppliers follow a meticulous process to ensure product quality and reliability:

Design and Engineering

Advanced CAD software is used to design pullers tailored to specific applications. Prototyping and testing ensure optimal performance and safety. South Korean engineers work closely with clients to develop custom solutions that meet unique requirements.

Material Selection

High-grade steel, alloys, and engineered plastics are chosen for durability and strength. The selection of materials is critical to the performance and longevity of pullers, especially for demanding industrial applications.

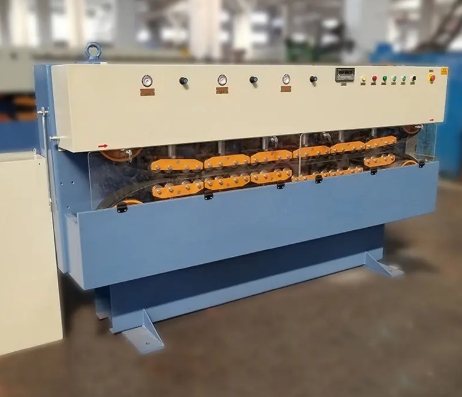

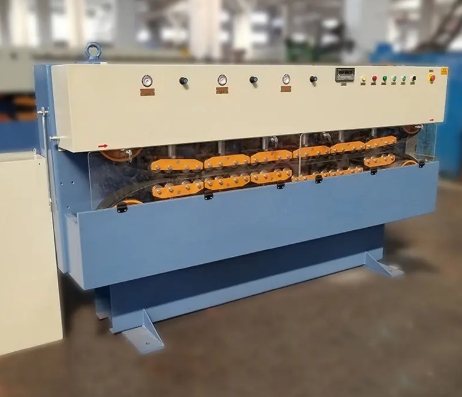

Precision Manufacturing

CNC machining, forging, and injection molding are employed for high-precision components. South Korean factories utilize state-of-the-art equipment to maintain tight tolerances and consistent quality. Automation and robotics are increasingly used to boost efficiency and reduce defects.

Assembly and Testing

Pullers are assembled by skilled technicians who follow strict quality control protocols. Each unit undergoes rigorous testing for load capacity, safety, and functionality. Testing may include stress tests, fatigue tests, and real-world simulations to ensure reliability.

Packaging and Delivery

Products are securely packaged for domestic and international shipping. OEM clients receive customized branding and packaging as required. South Korean suppliers leverage efficient logistics networks to ensure timely delivery worldwide.

Why Choose South Korean Puller Manufacturers And Suppliers?

Superior Quality

South Korean puller manufacturers and suppliers adhere to international quality standards, ensuring products are reliable and long-lasting. Certifications such as ISO 9001 and CE mark are common among leading companies.

Innovation and Technology

Continuous investment in research and development leads to innovative products that meet the latest industry demands. South Korean puller suppliers are at the forefront of integrating smart technologies, such as IoT-enabled tools and advanced materials.

Customization and OEM Services

Manufacturers offer flexible OEM and ODM services, allowing clients to customize products according to their specifications. This includes bespoke designs, branding, and packaging to support global marketing strategies.

Competitive Pricing

Efficient manufacturing processes and economies of scale enable competitive pricing without compromising quality. South Korean suppliers are known for balancing cost-effectiveness with high standards.

Global Logistics

South Korean suppliers have robust logistics networks, ensuring timely delivery to clients worldwide. Their experience with international shipping regulations and documentation simplifies the import process for global buyers.

OEM Services and Global Partnerships

Many South Korean puller manufacturers and suppliers specialize in OEM services, catering to international brands, wholesalers, and manufacturers. These partnerships are built on trust, quality, and mutual growth. OEM clients benefit from:

- Custom product development

- Private labeling and branding

- Flexible order quantities

- Comprehensive after-sales support

South Korean companies understand the importance of confidentiality and intellectual property protection, making them reliable partners for global brands seeking to expand their product lines.

Puller Applications Across Industries

Pullers manufactured in South Korea are used across a wide variety of industries, demonstrating their versatility and reliability.

Automotive Industry

Automotive workshops and manufacturers rely on pullers for tasks such as removing bearings, gears, and pulleys. South Korean puller suppliers provide tools that are robust, easy to use, and designed for rapid maintenance.

Construction and Heavy Equipment

Hydraulic and cable pullers are essential in construction, where they are used to install and remove heavy components, tension cables, and perform maintenance on machinery. The durability and strength of South Korean pullers make them a preferred choice for demanding environments.

Electrical and Utility Sectors

Cable pullers are indispensable for electrical installation and maintenance. South Korean manufacturers produce pullers that meet high safety standards, ensuring reliable performance in critical infrastructure projects.

Textile and Apparel

Zipper pullers and related accessories are a significant export for South Korea. Leading global brands source zipper pullers from South Korean suppliers due to their quality, design flexibility, and ability to meet large-scale orders.

Manufacturing and Maintenance

General manufacturing plants use pullers for equipment maintenance, assembly, and disassembly. The precision and reliability of South Korean pullers contribute to reduced downtime and improved operational efficiency.

Key Considerations When Selecting a Puller Supplier

Choosing the right puller manufacturer or supplier is crucial for ensuring product quality, timely delivery, and long-term partnership success. Here are some key factors to consider:

Product Range and Specialization

Evaluate whether the supplier offers the specific types of pullers you need, and whether they have expertise in your industry.

Quality Assurance

Check for certifications, quality control processes, and customer testimonials to assess the supplier's commitment to quality.

Customization Capabilities

If you require OEM or custom products, ensure the supplier has the technical expertise and production capacity to meet your requirements.

Communication and Support

Effective communication is essential for successful partnerships. Choose suppliers who are responsive, transparent, and provide comprehensive after-sales support.

Logistics and Delivery

Consider the supplier's experience with international shipping, packaging standards, and ability to meet your delivery timelines.

The Future of Puller Manufacturing in South Korea

The puller manufacturing industry in South Korea is poised for continued growth and innovation. As global demand for high-quality industrial tools increases, South Korean manufacturers are investing in smart manufacturing technologies, automation, and sustainable production practices.

Emerging trends include:

- Integration of IoT and Smart Sensors: Pullers with embedded sensors for real-time monitoring and predictive maintenance.

- Eco-friendly Materials: Adoption of recyclable and sustainable materials in puller production.

- Advanced Coatings and Surface Treatments: Enhancing durability and corrosion resistance.

- Expansion into New Markets: South Korean suppliers are increasingly targeting emerging markets in Southeast Asia, the Middle East, and Africa.

With a strong foundation in quality, innovation, and customer service, South Korean puller manufacturers and suppliers are well-positioned to lead the global market for years to come.

Conclusion

South Korea is home to a dynamic and innovative puller manufacturing industry, offering a wide range of high-quality products for global markets. With a focus on quality, technology, and customer service, South Korean puller manufacturers and suppliers are trusted partners for OEM clients, wholesalers, and manufacturers worldwide. Their advanced manufacturing processes, flexible OEM services, and commitment to excellence make them a top choice for anyone seeking reliable puller solutions. As the industry continues to evolve, South Korea remains at the forefront of puller innovation, setting new standards for performance and reliability.

Frequently Asked Questions (FAQ)

1. What types of pullers do South Korean manufacturers produce?

South Korean puller manufacturers and suppliers produce mechanical, hydraulic, gear, cable, and zipper pullers, catering to a wide range of industries including automotive, construction, textiles, and heavy machinery.

2. Can South Korean puller manufacturers provide OEM services?

Yes, many puller manufacturers and suppliers in South Korea offer OEM and ODM services, allowing clients to customize products, branding, and packaging to meet their specific requirements.

3. How do South Korean puller manufacturers ensure product quality?

Manufacturers implement strict quality control measures, use high-grade materials, and conduct rigorous testing at every stage of production to ensure reliability and safety.

4. What are the advantages of sourcing pullers from South Korea?

Advantages include superior product quality, innovative designs, competitive pricing, flexible OEM services, and efficient global logistics.

5. How can I contact top puller manufacturers and suppliers in South Korea?

You can find detailed contact information, product catalogs, and company profiles on industry platforms such as Trademo, Komachine, and tradeKorea.